WORKS

PIECES

View Pieces that are currently available in specific galleries.

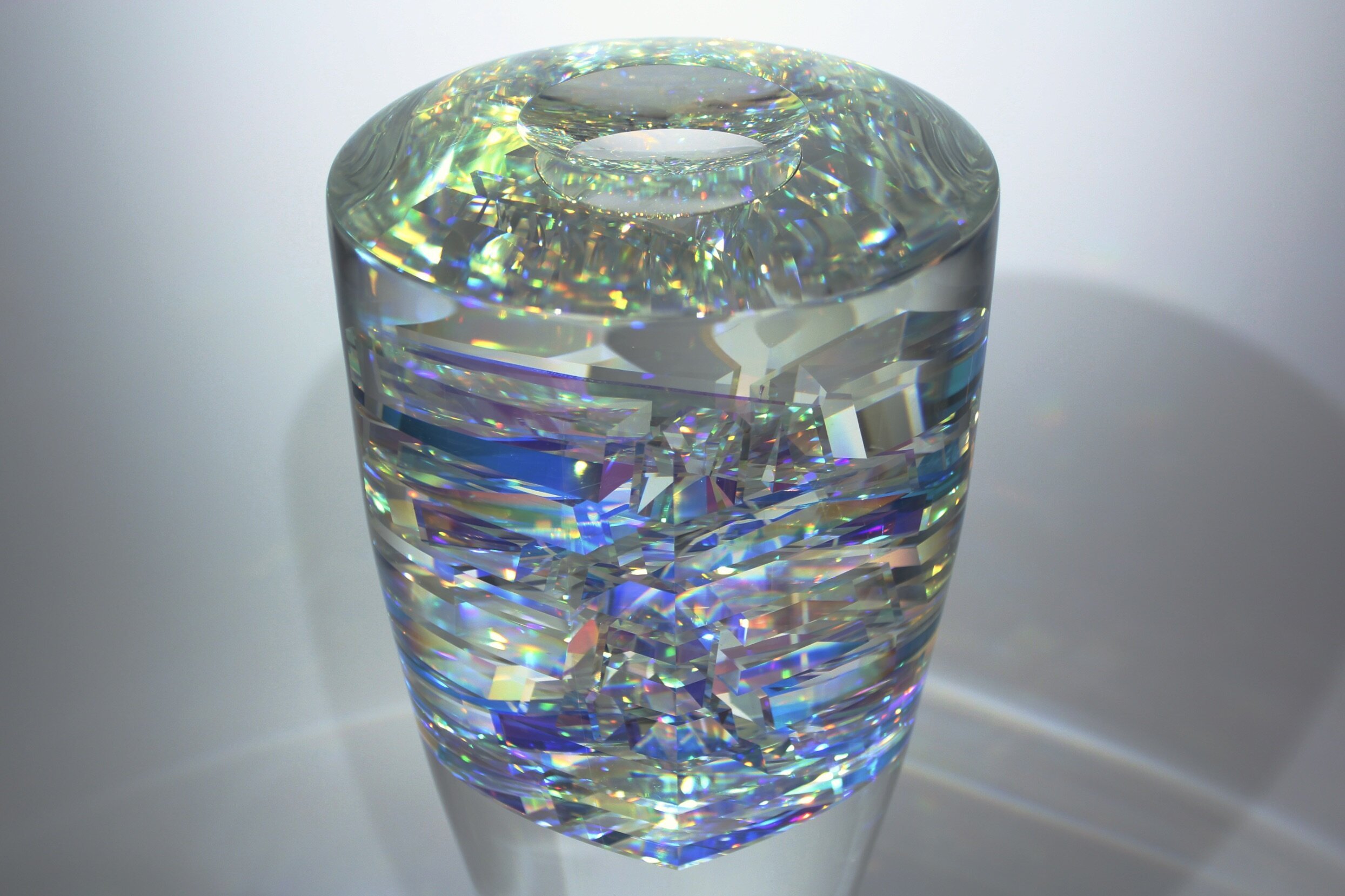

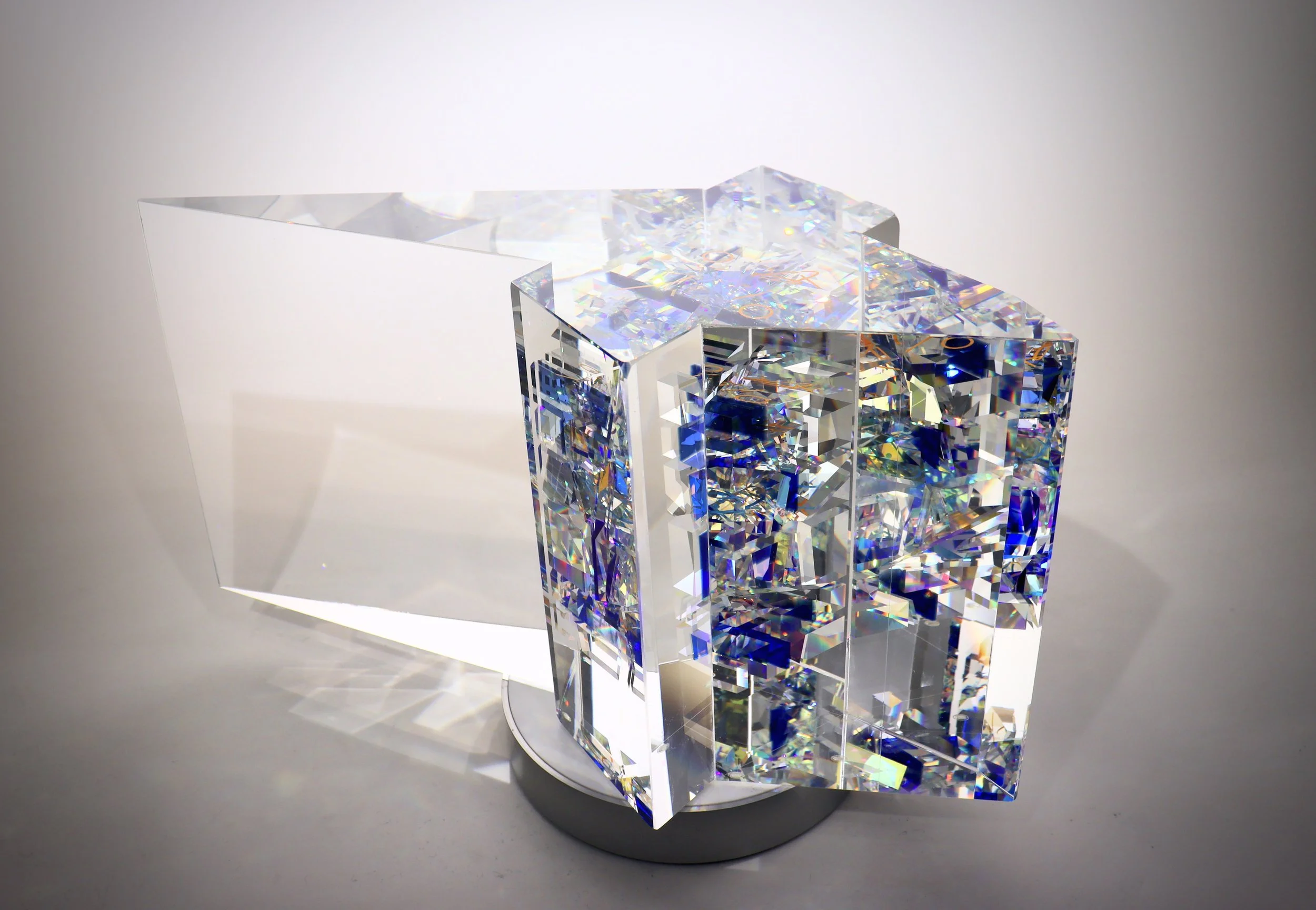

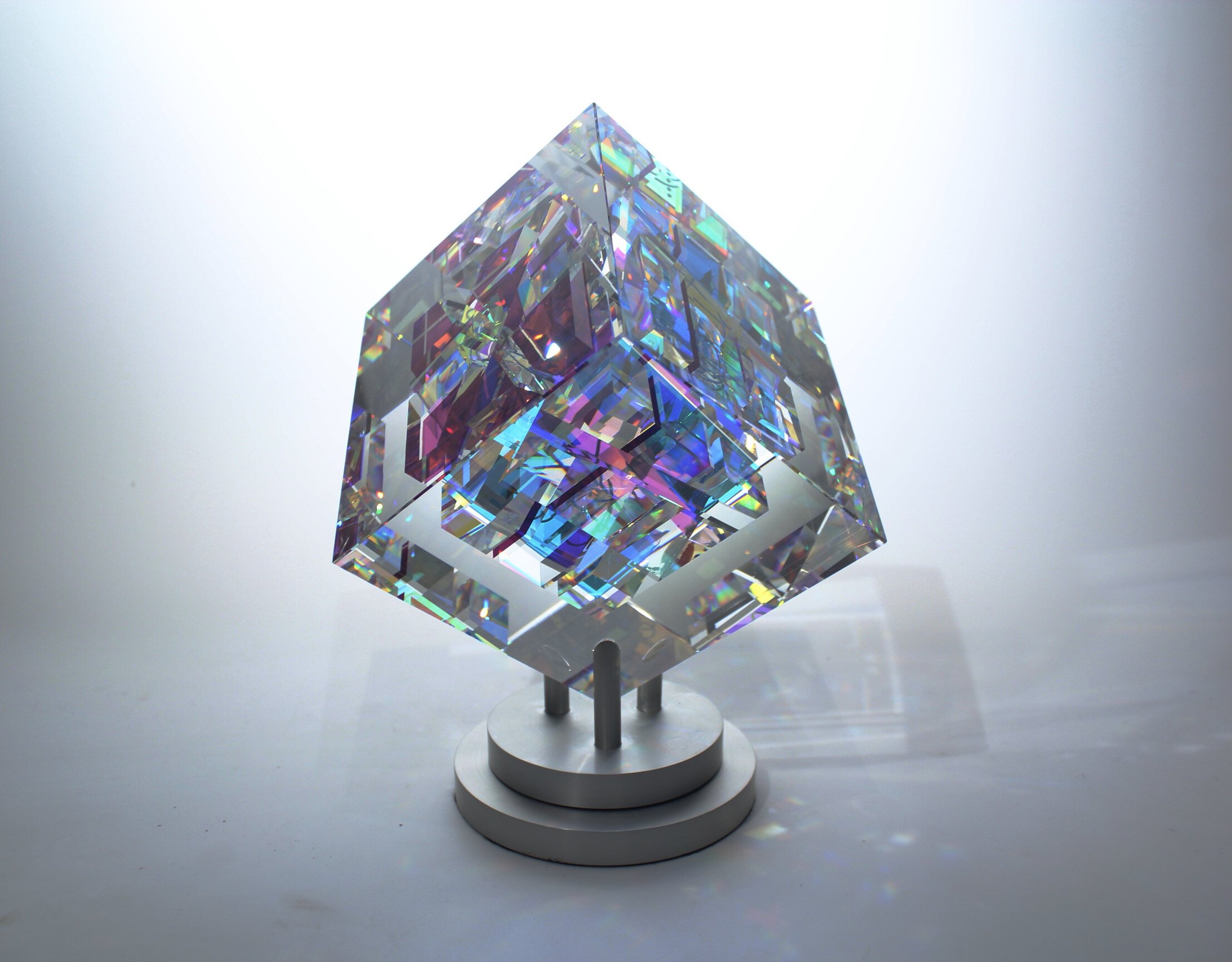

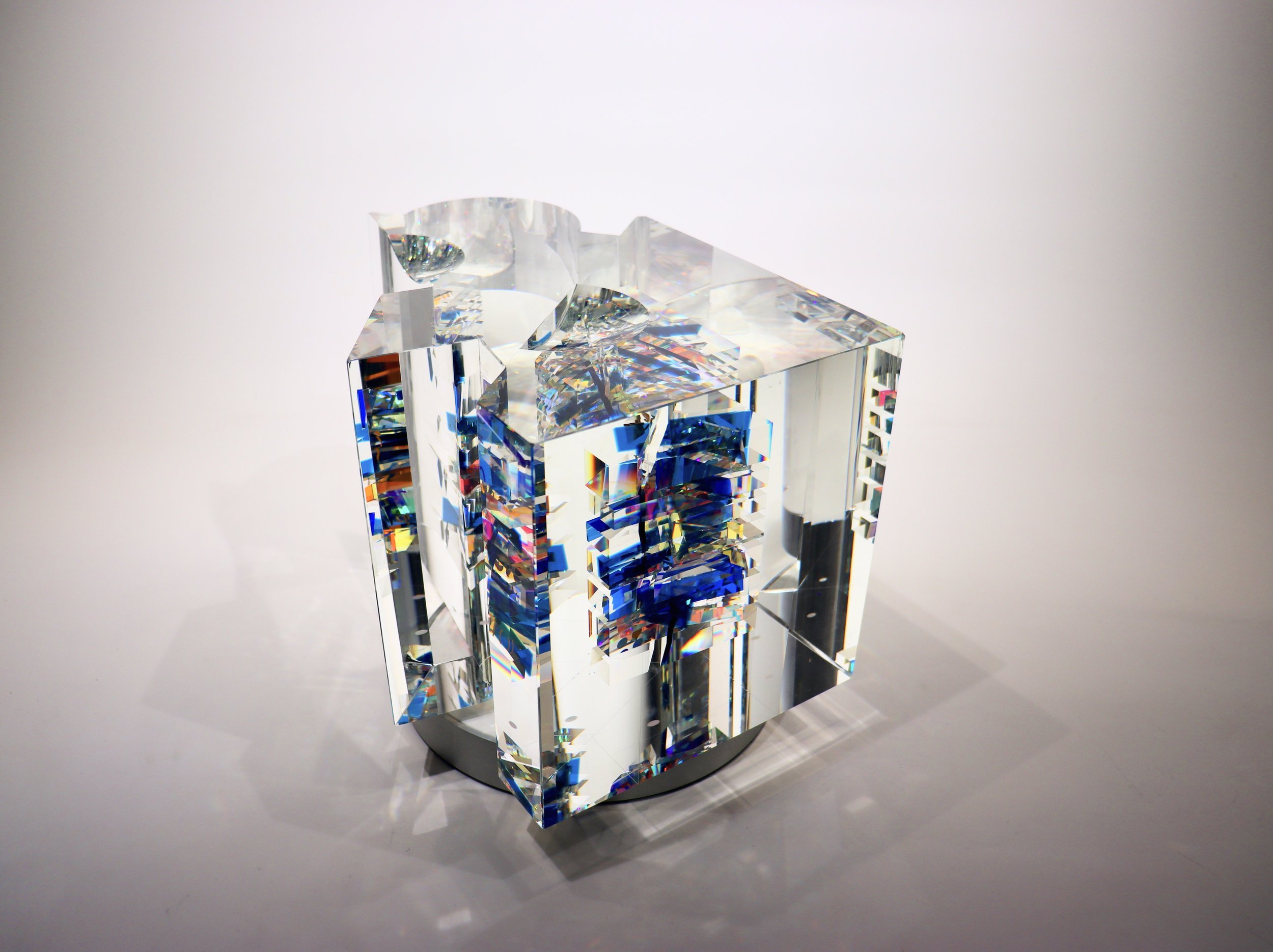

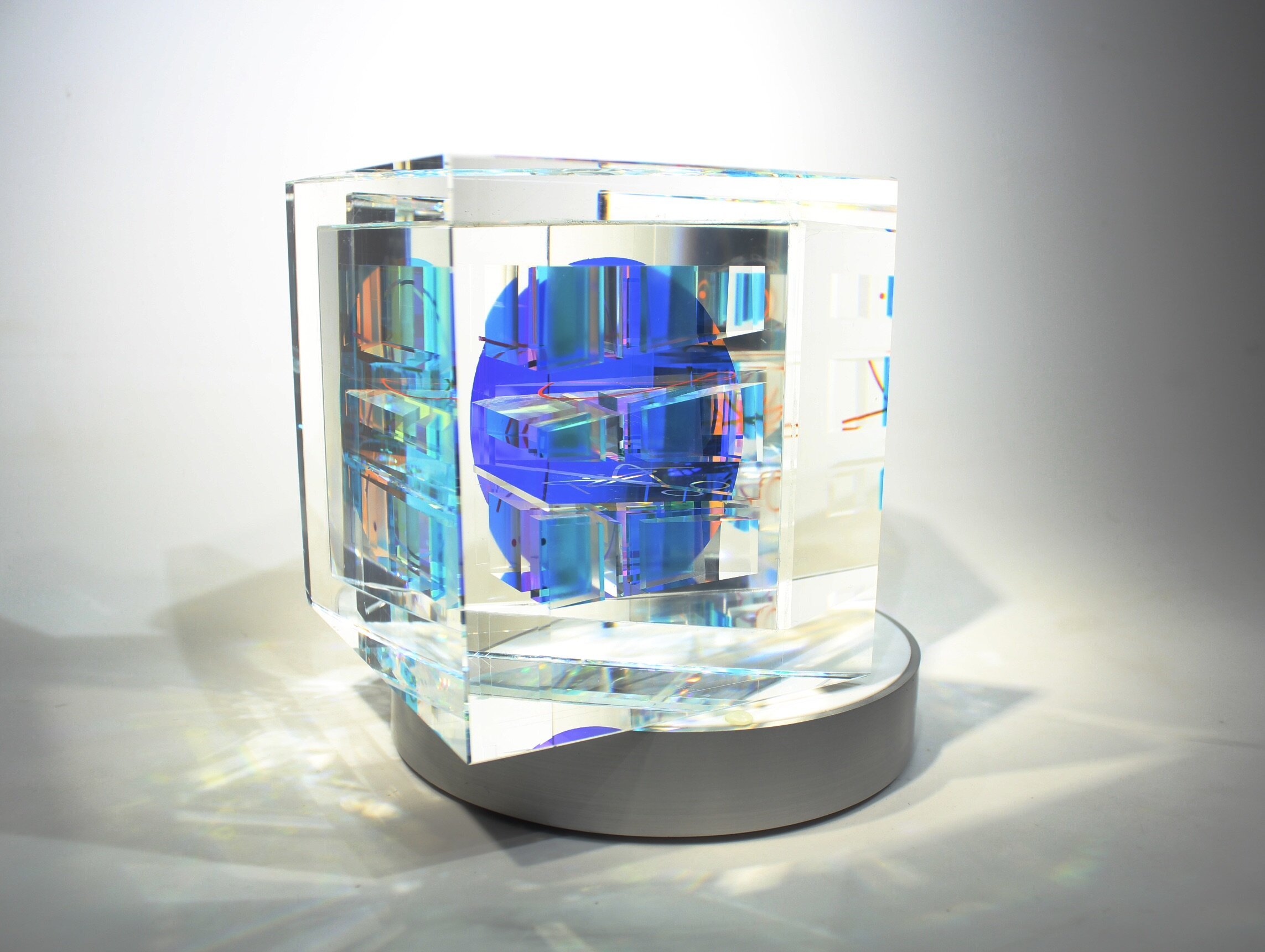

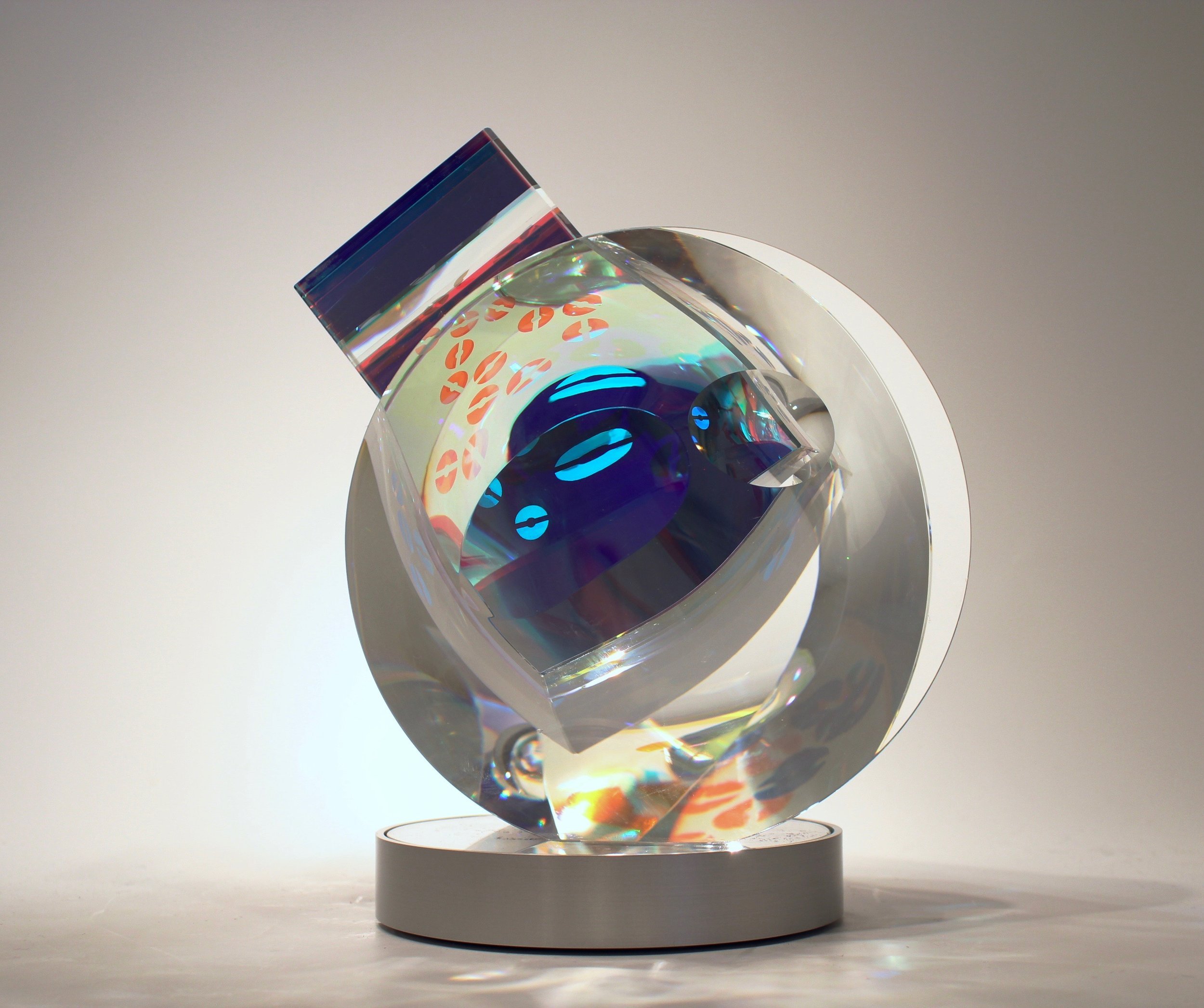

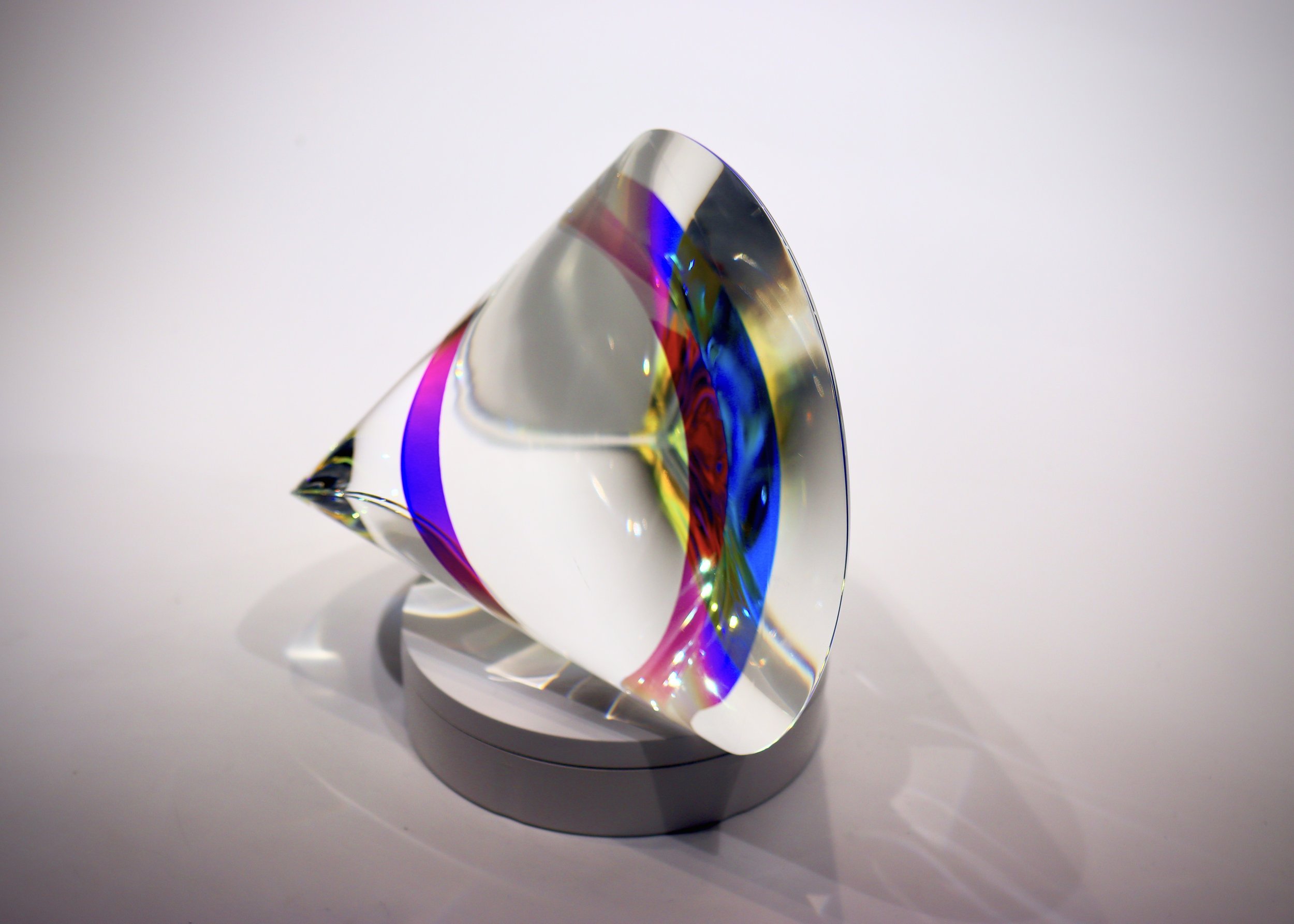

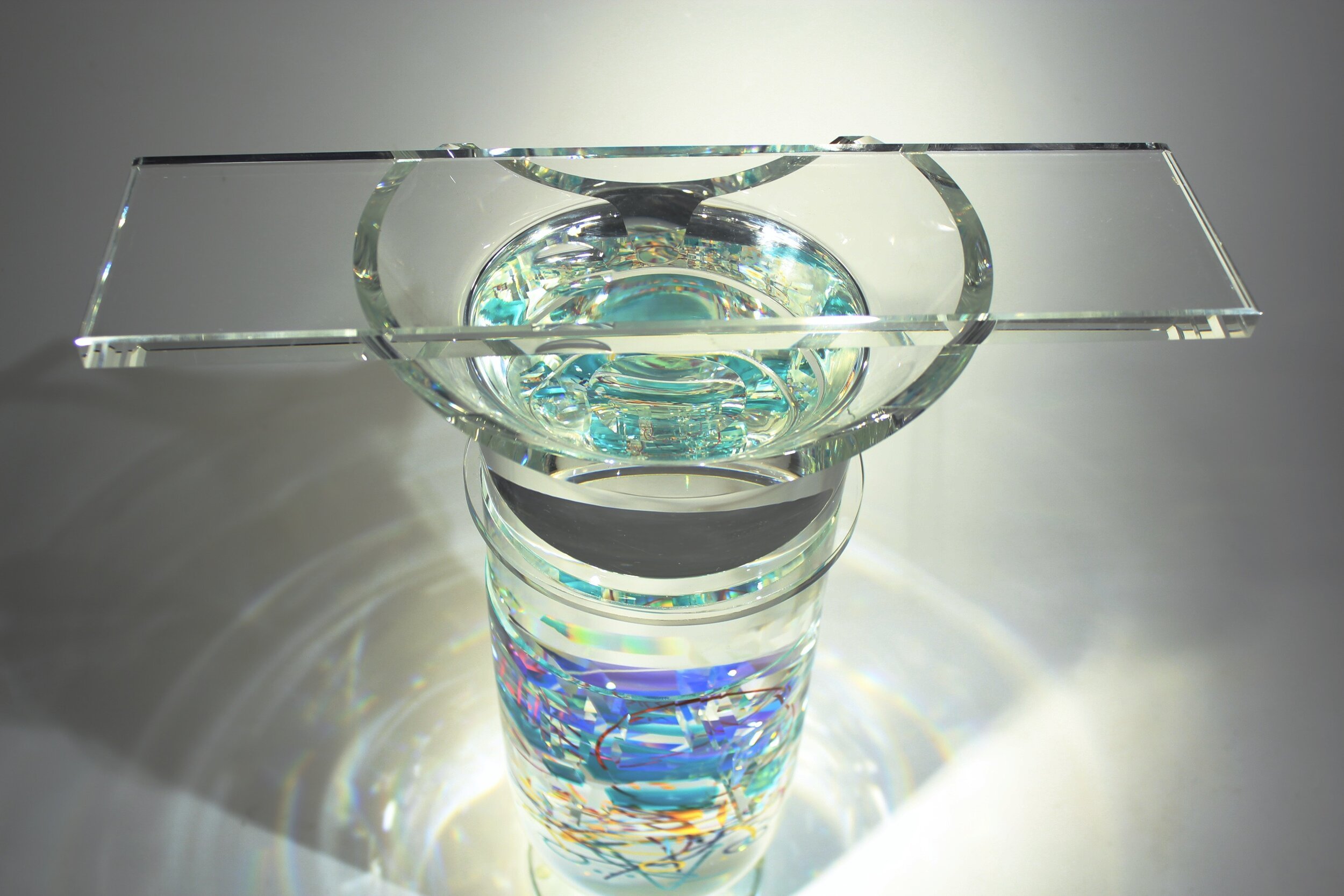

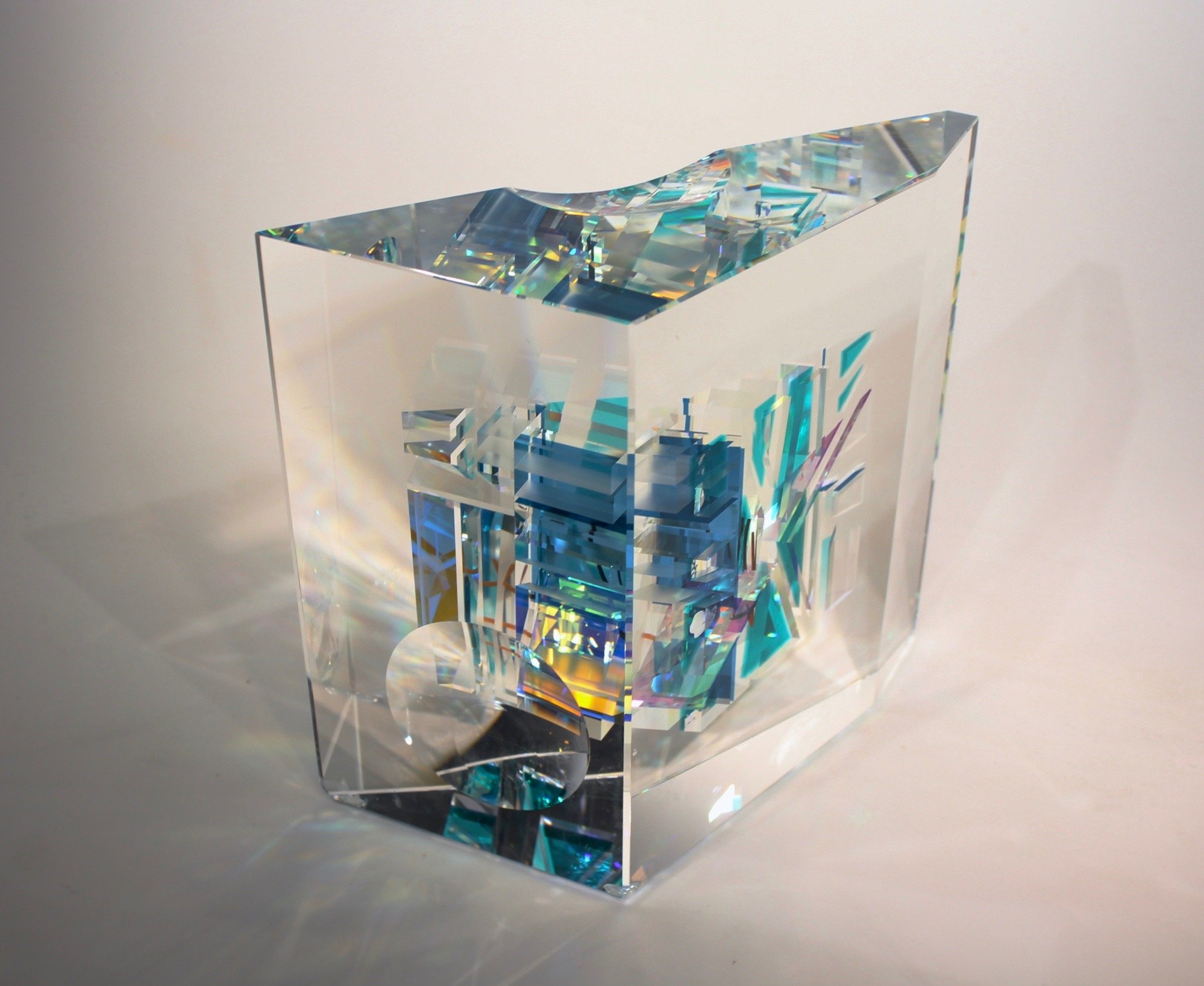

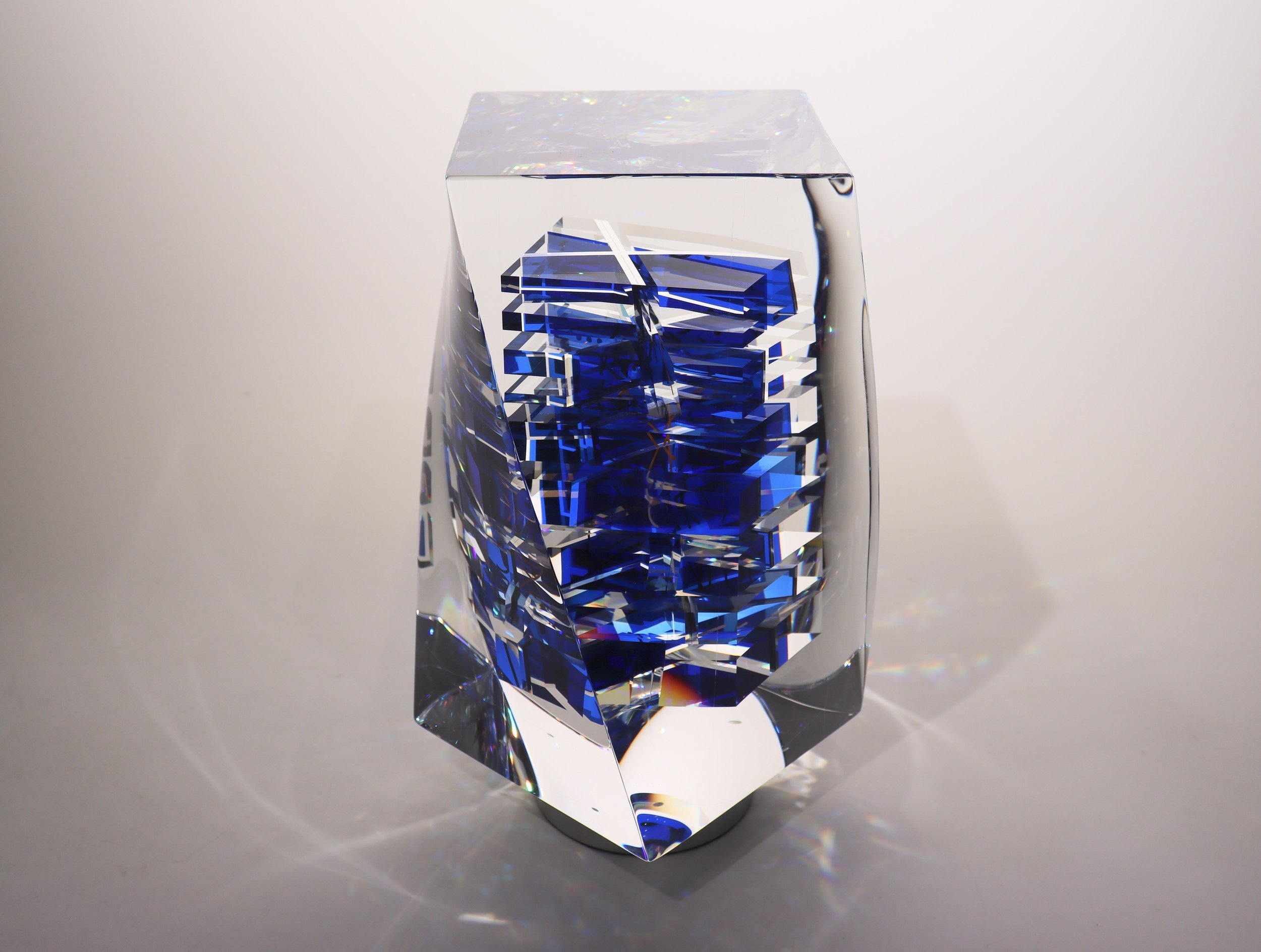

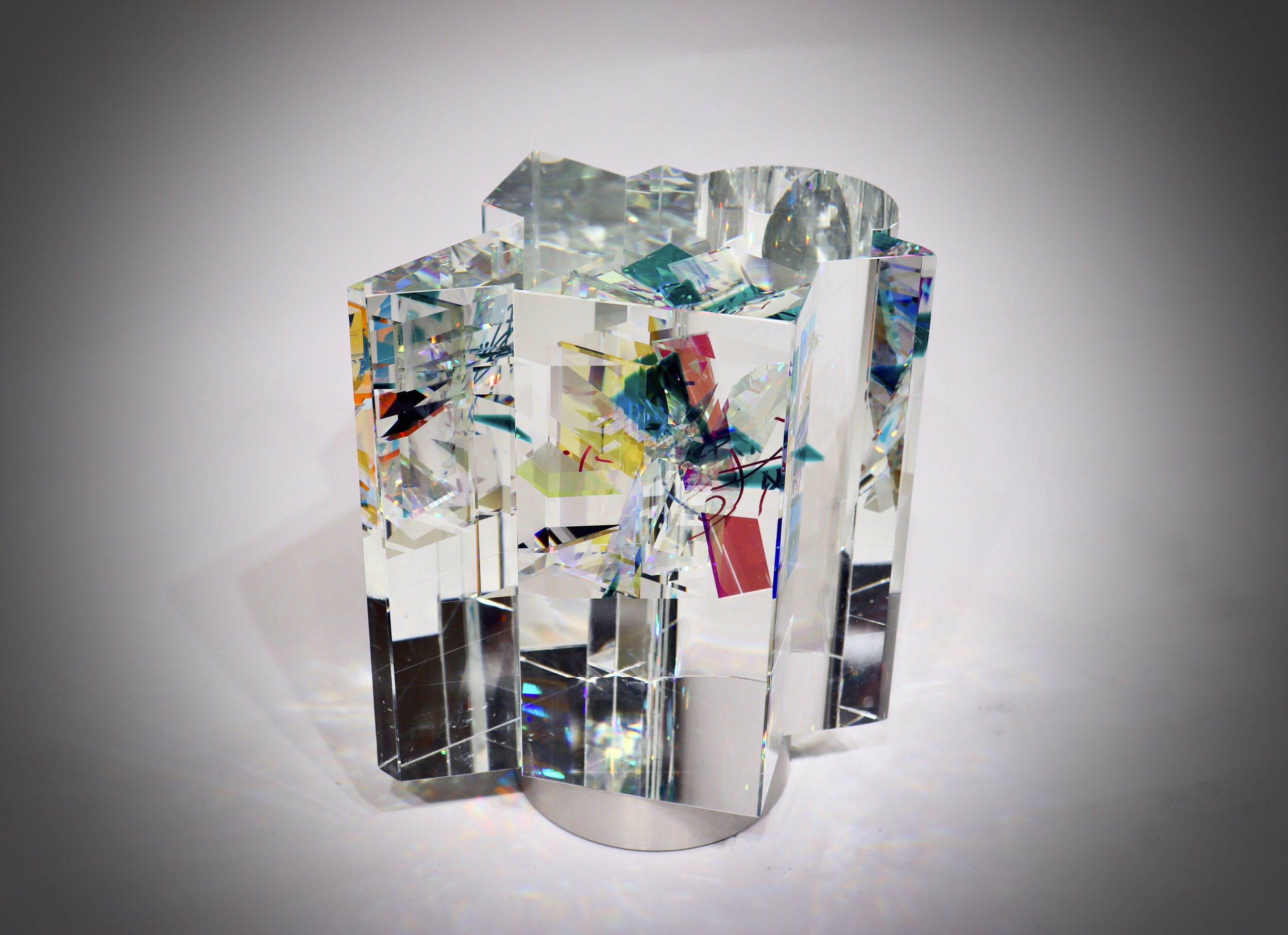

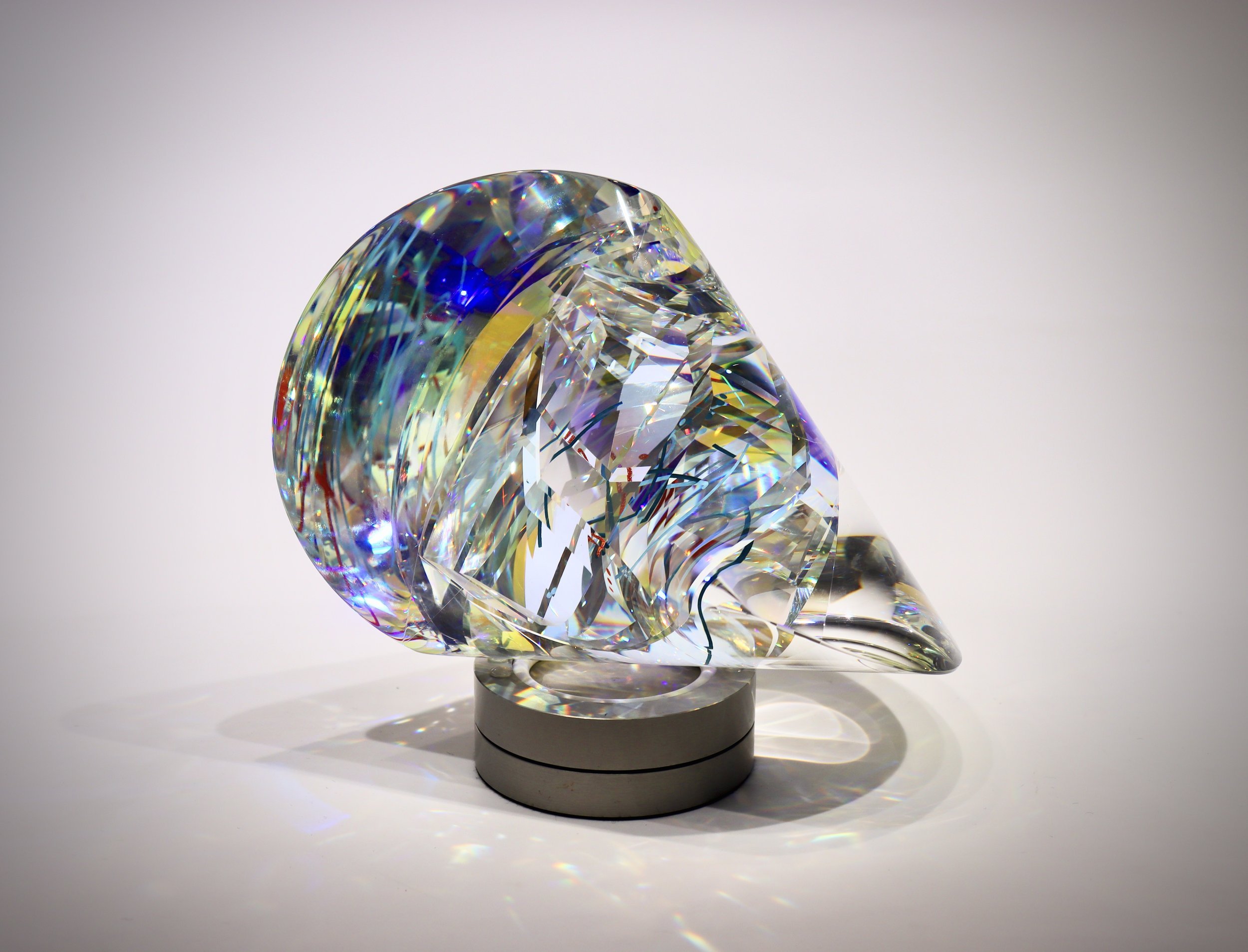

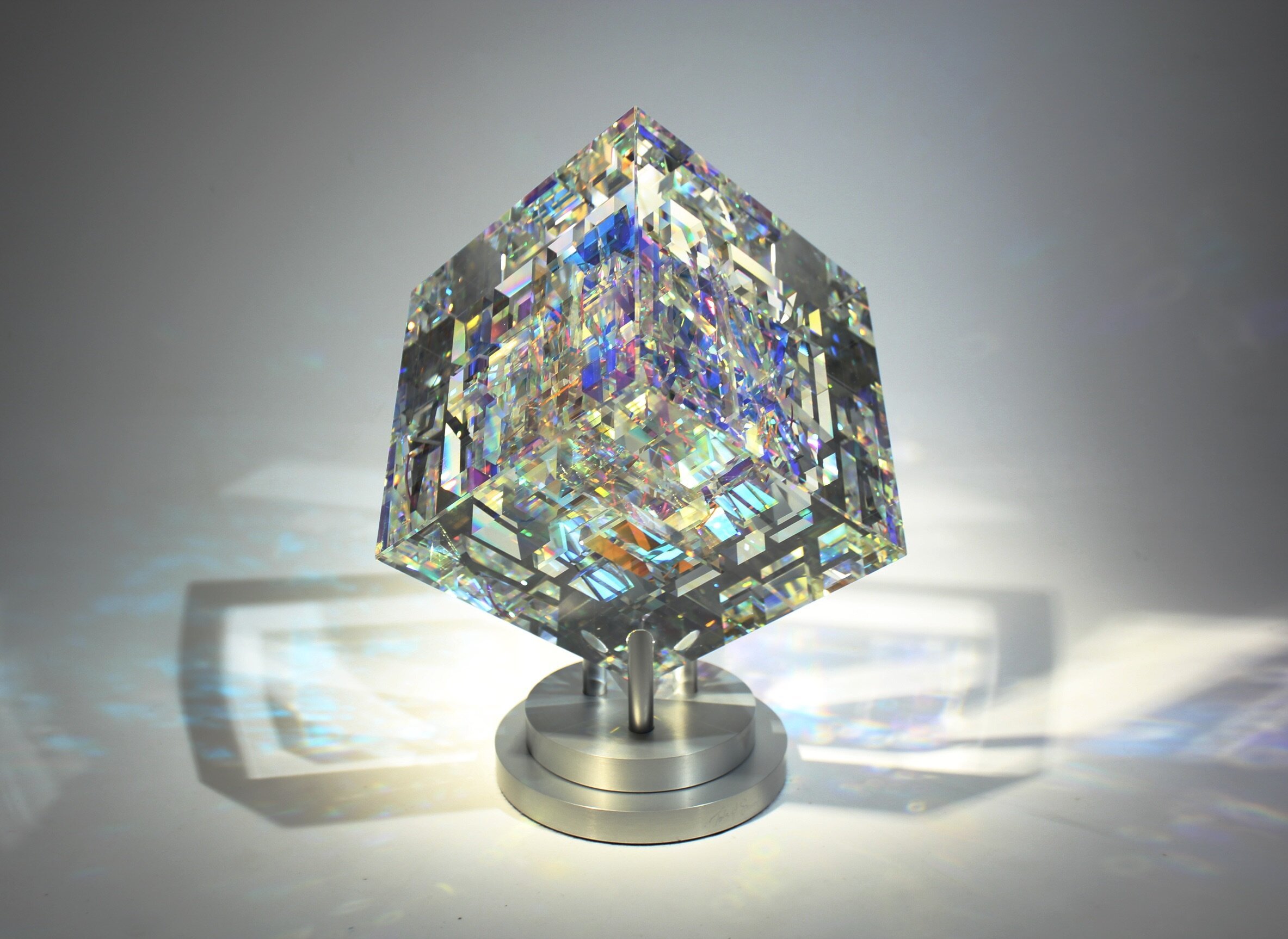

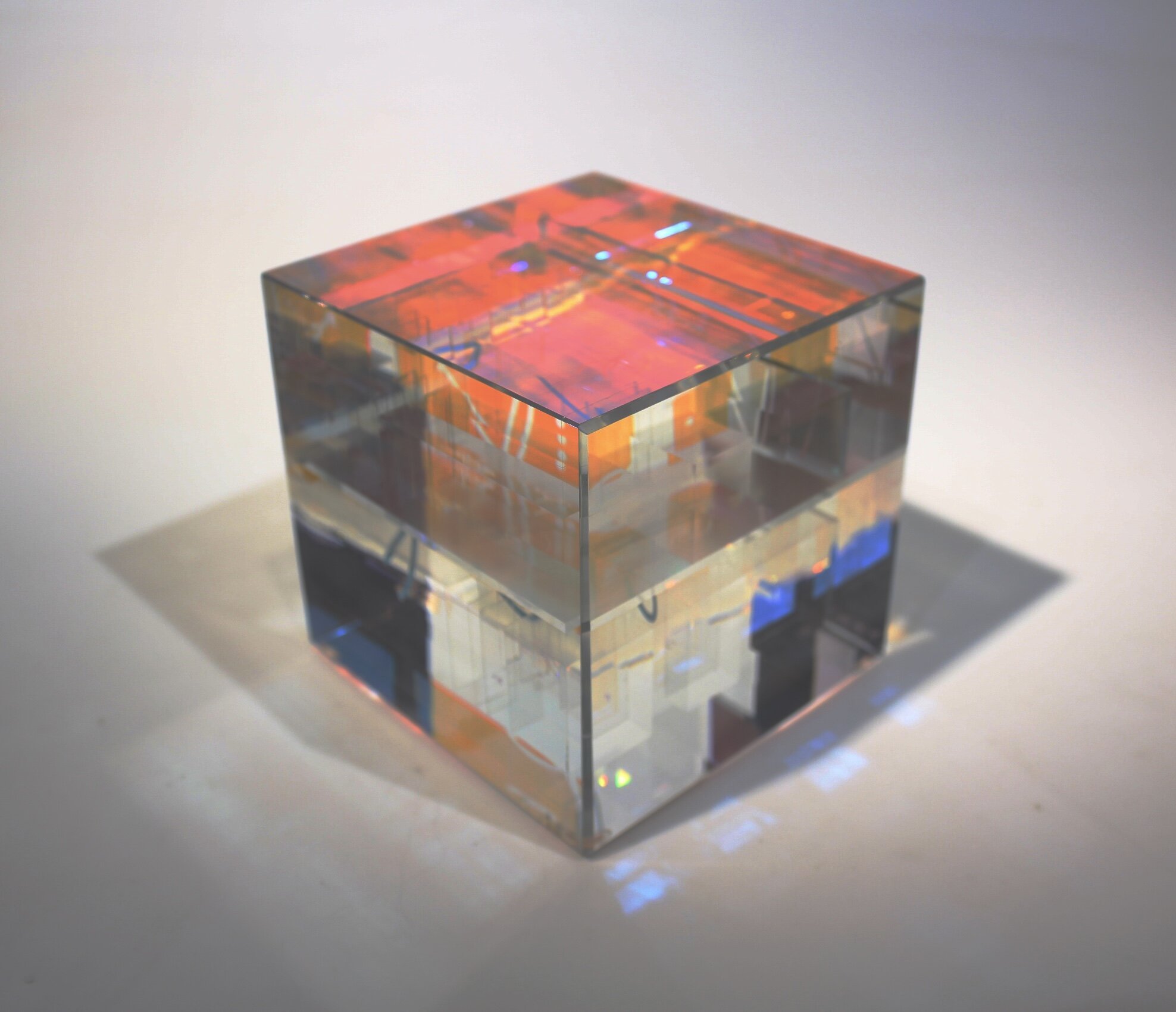

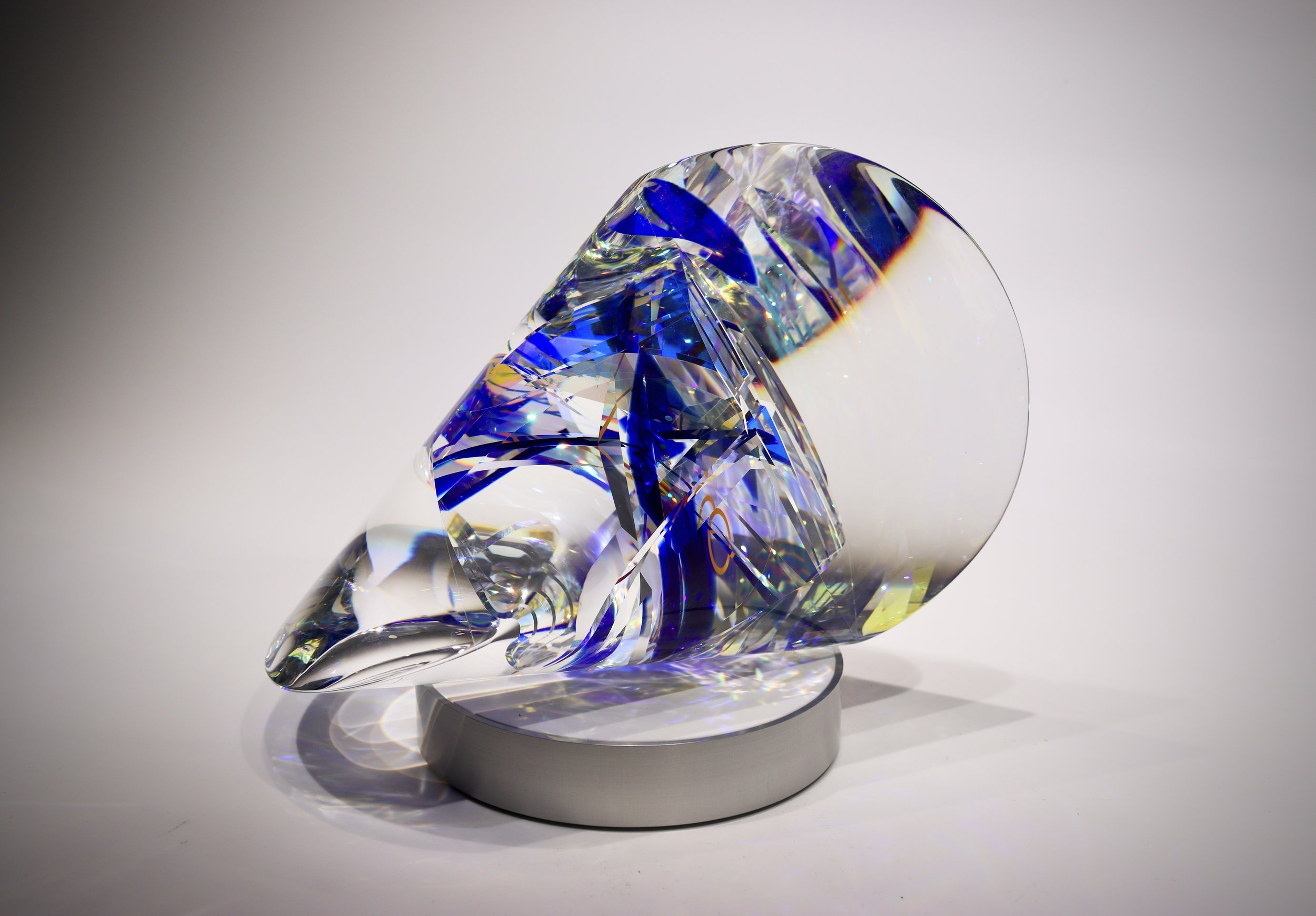

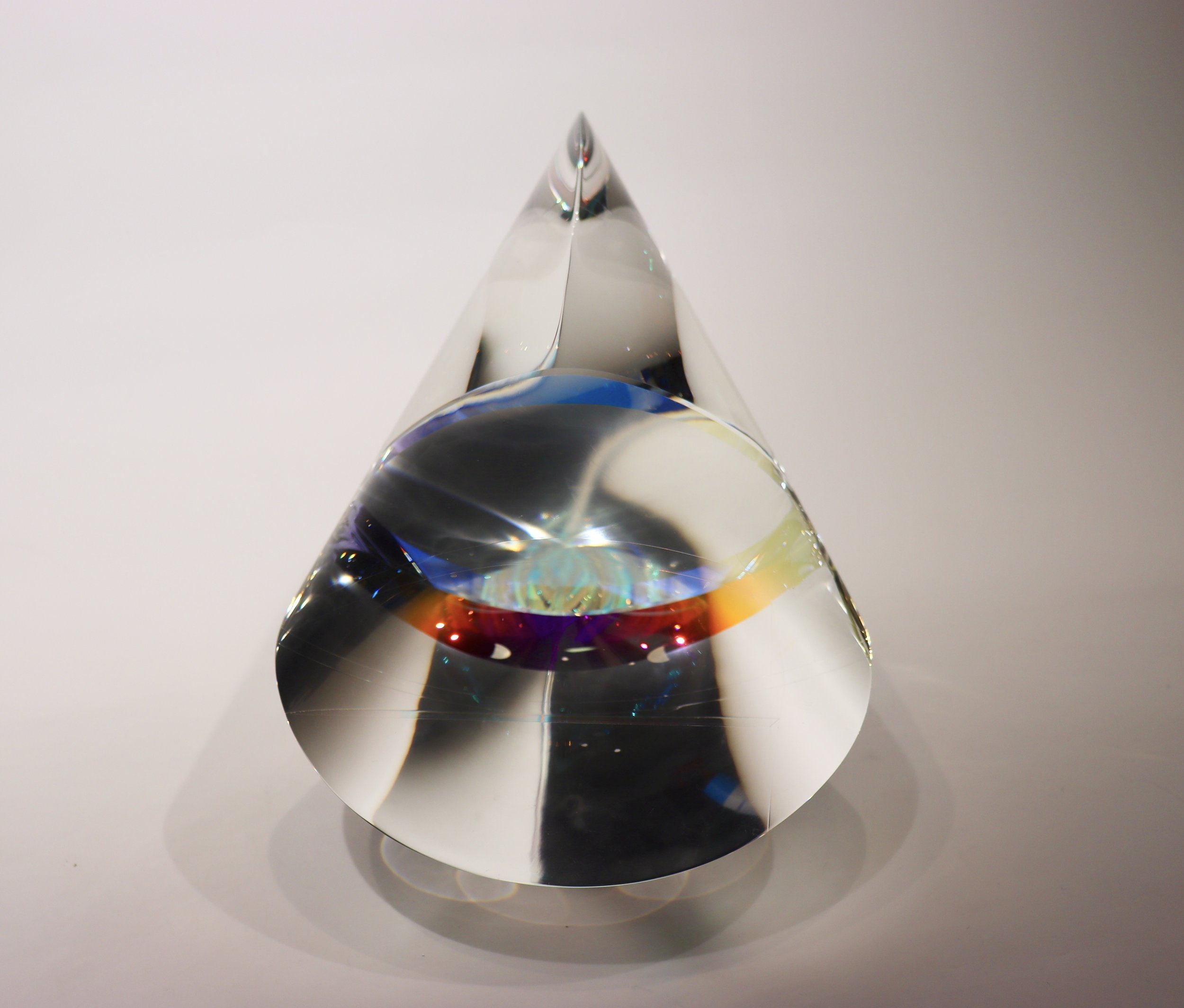

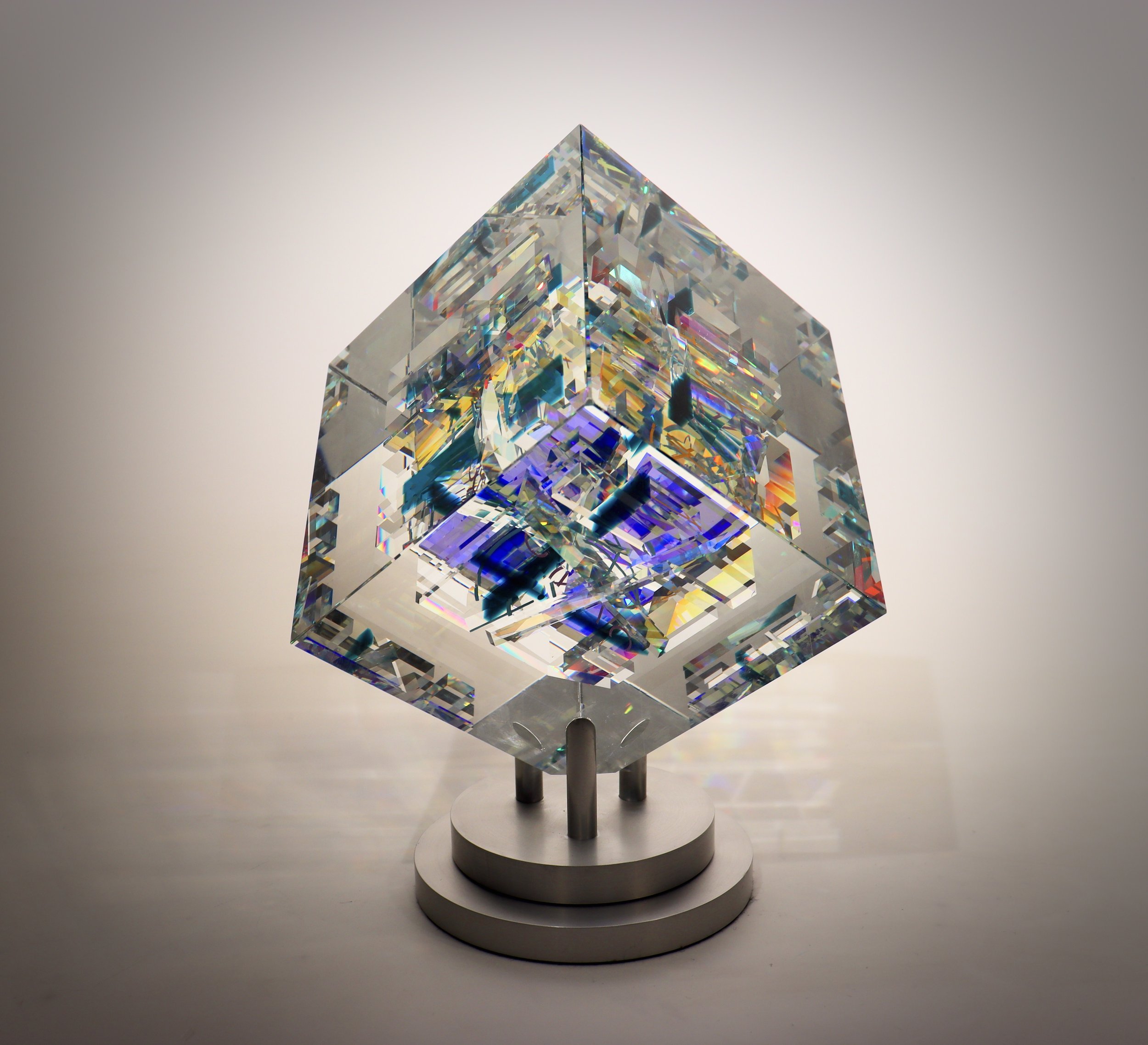

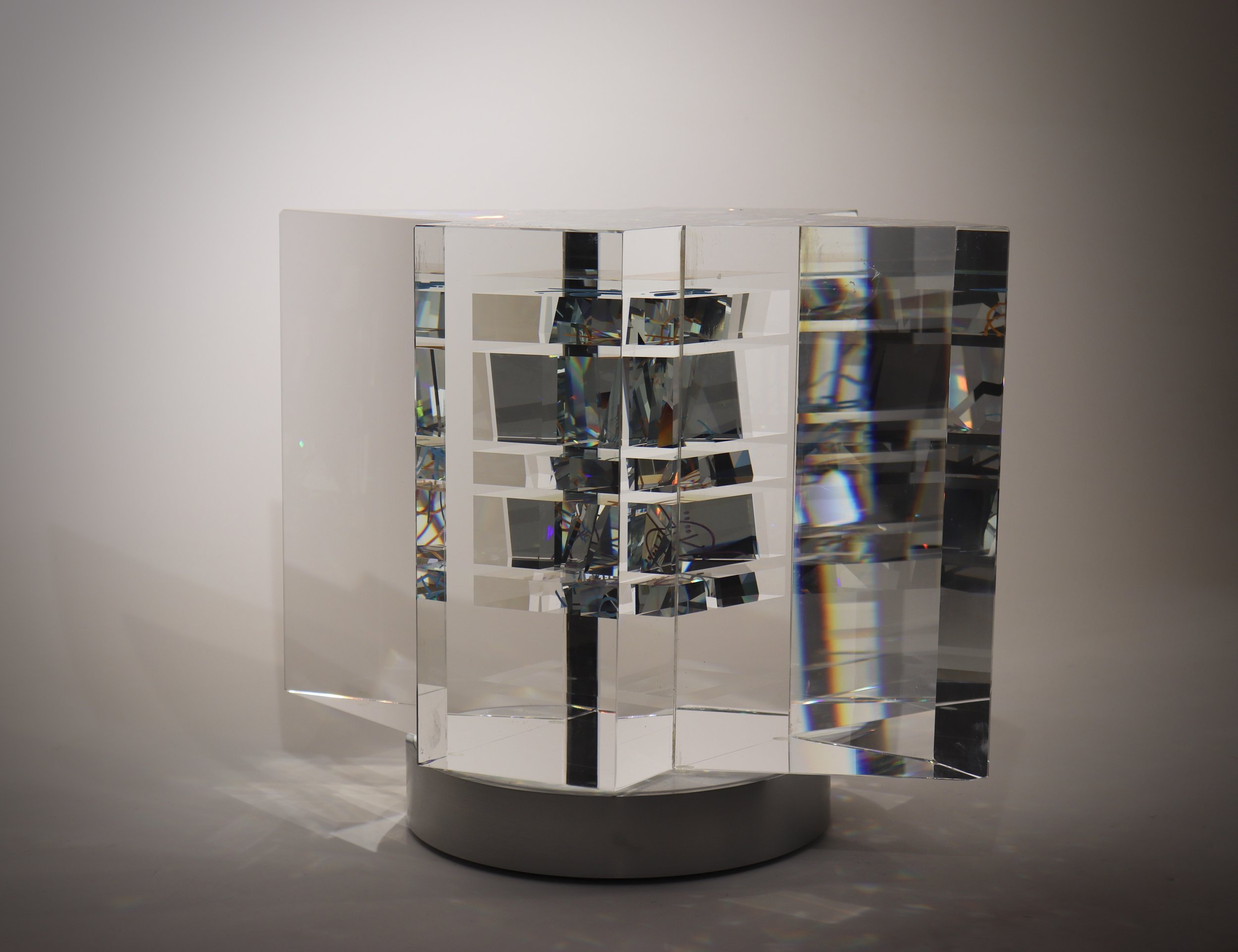

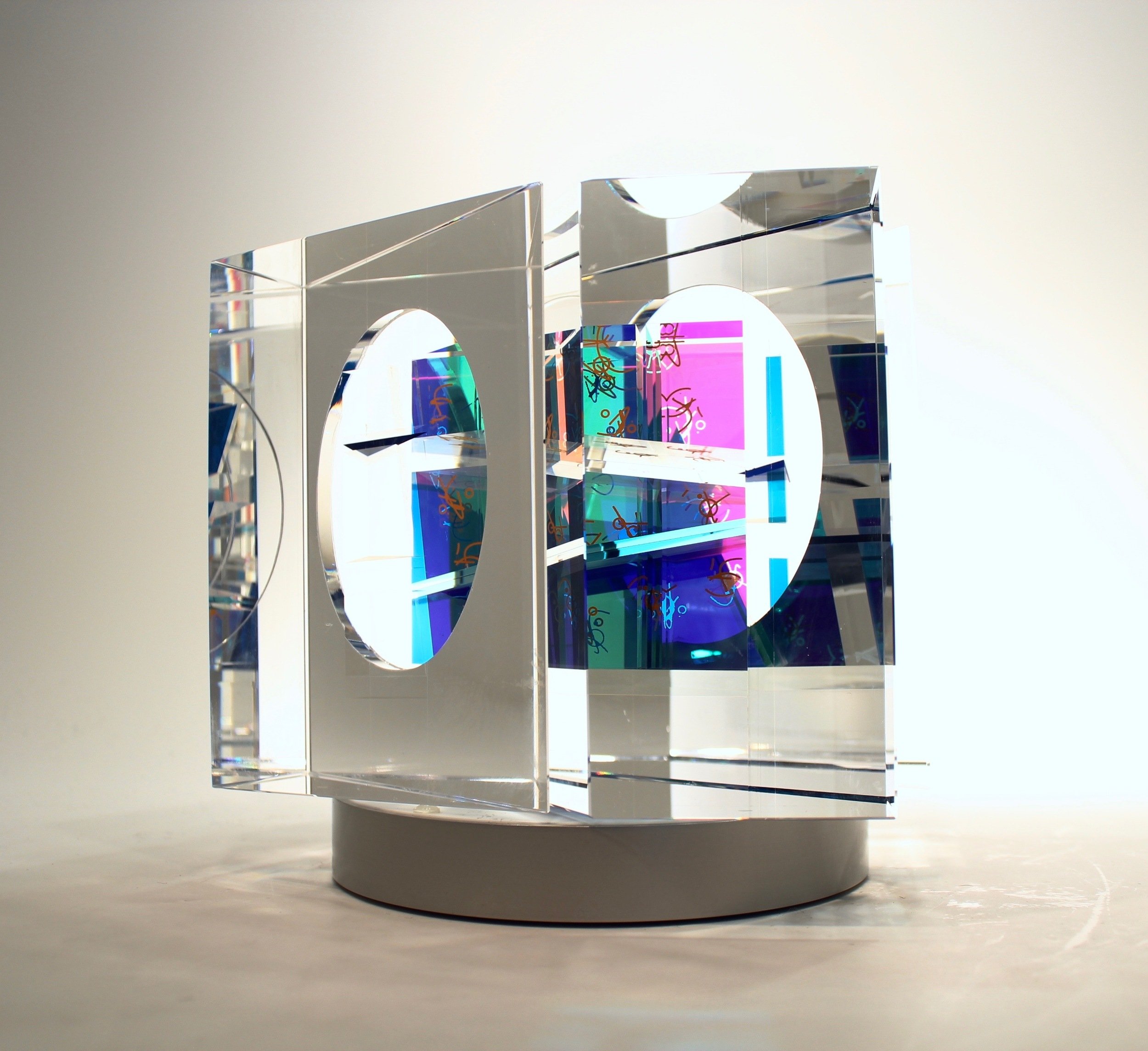

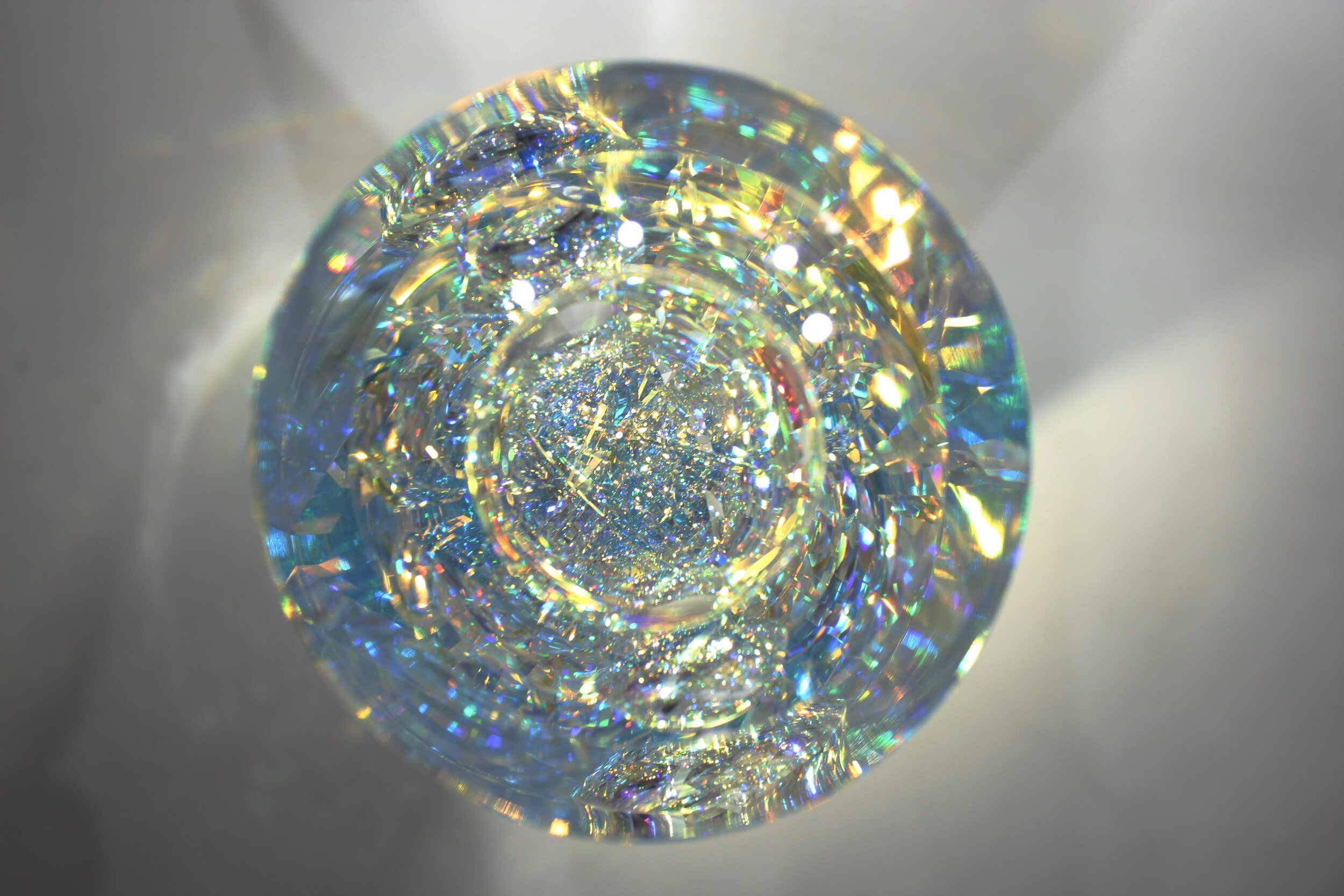

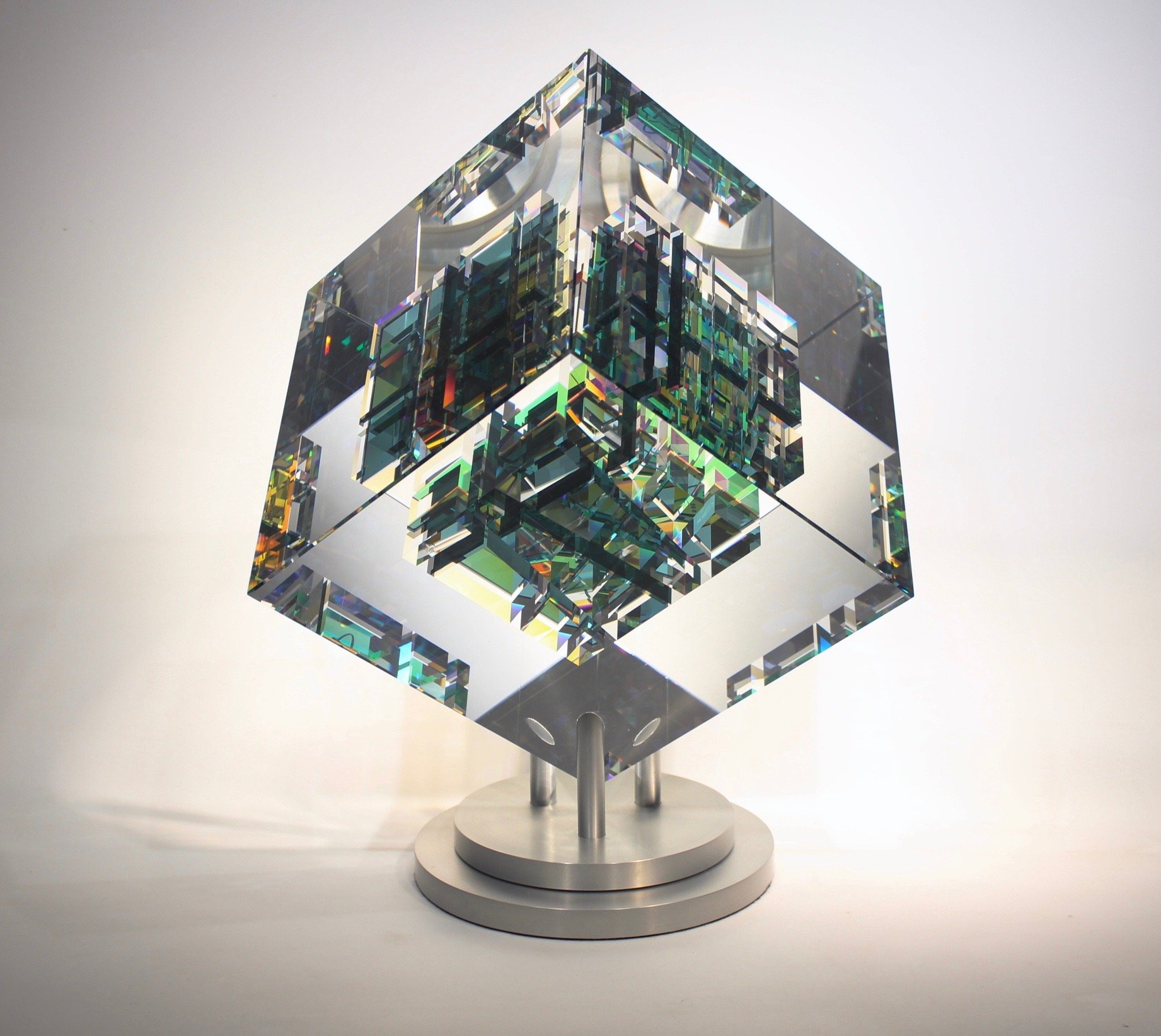

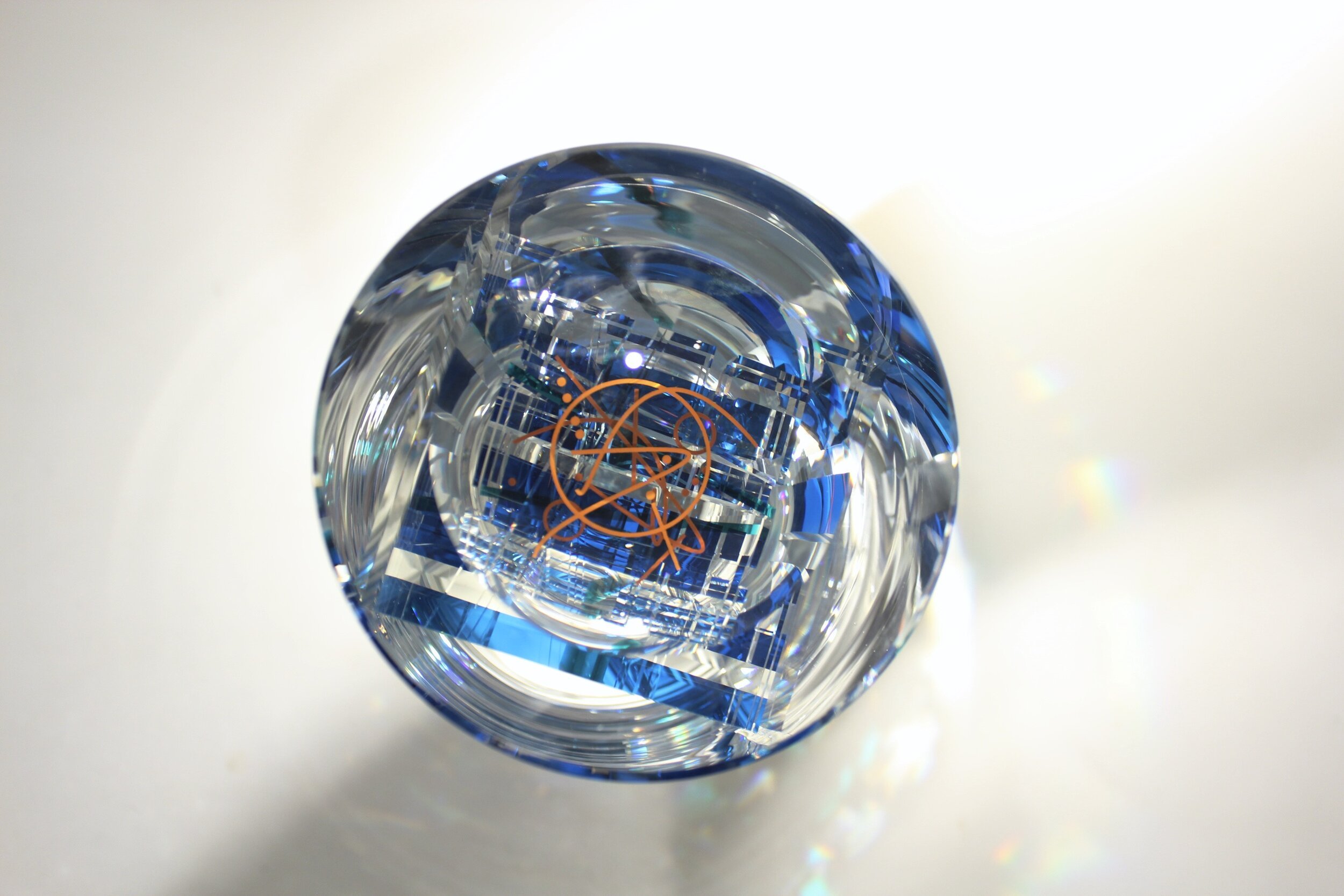

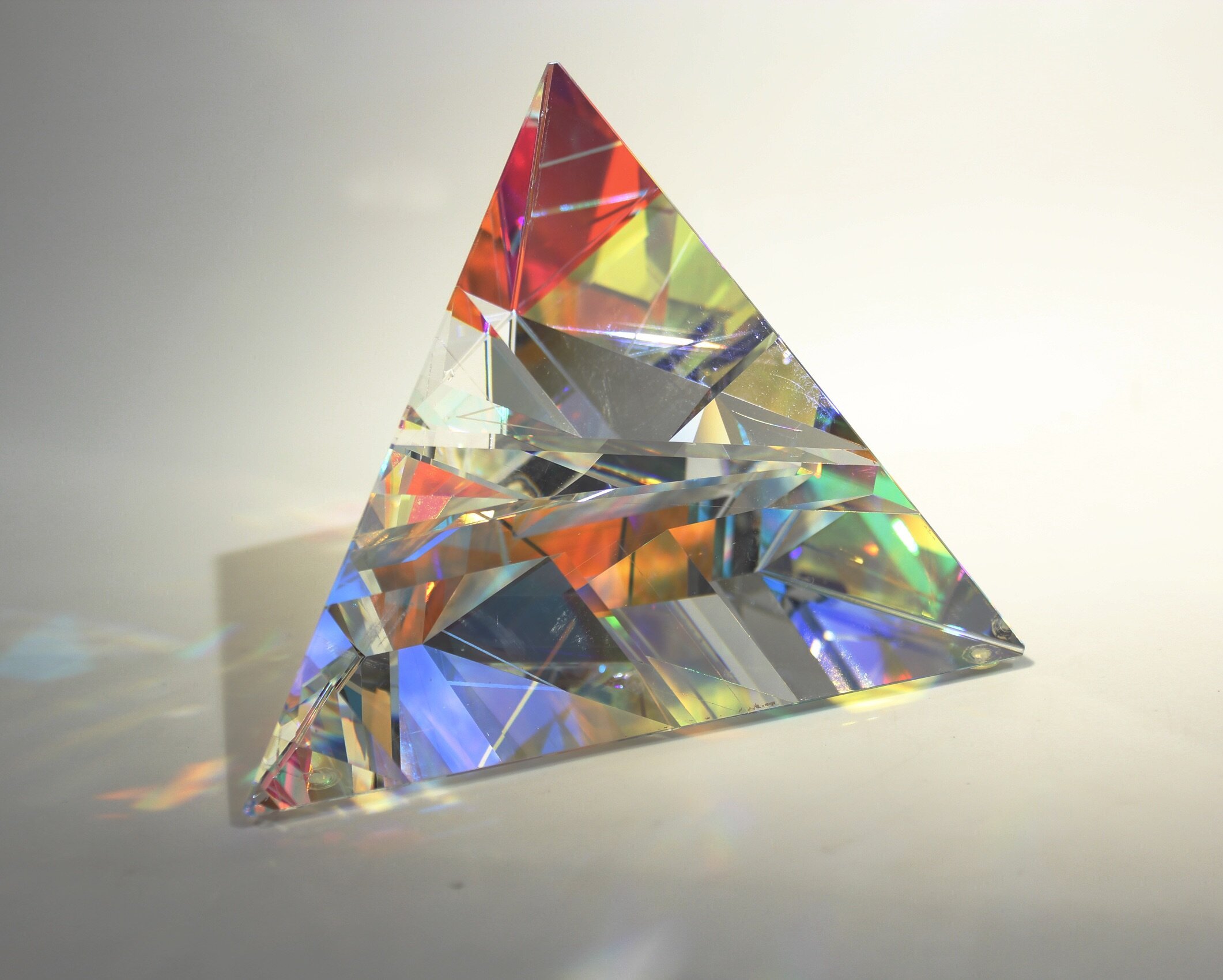

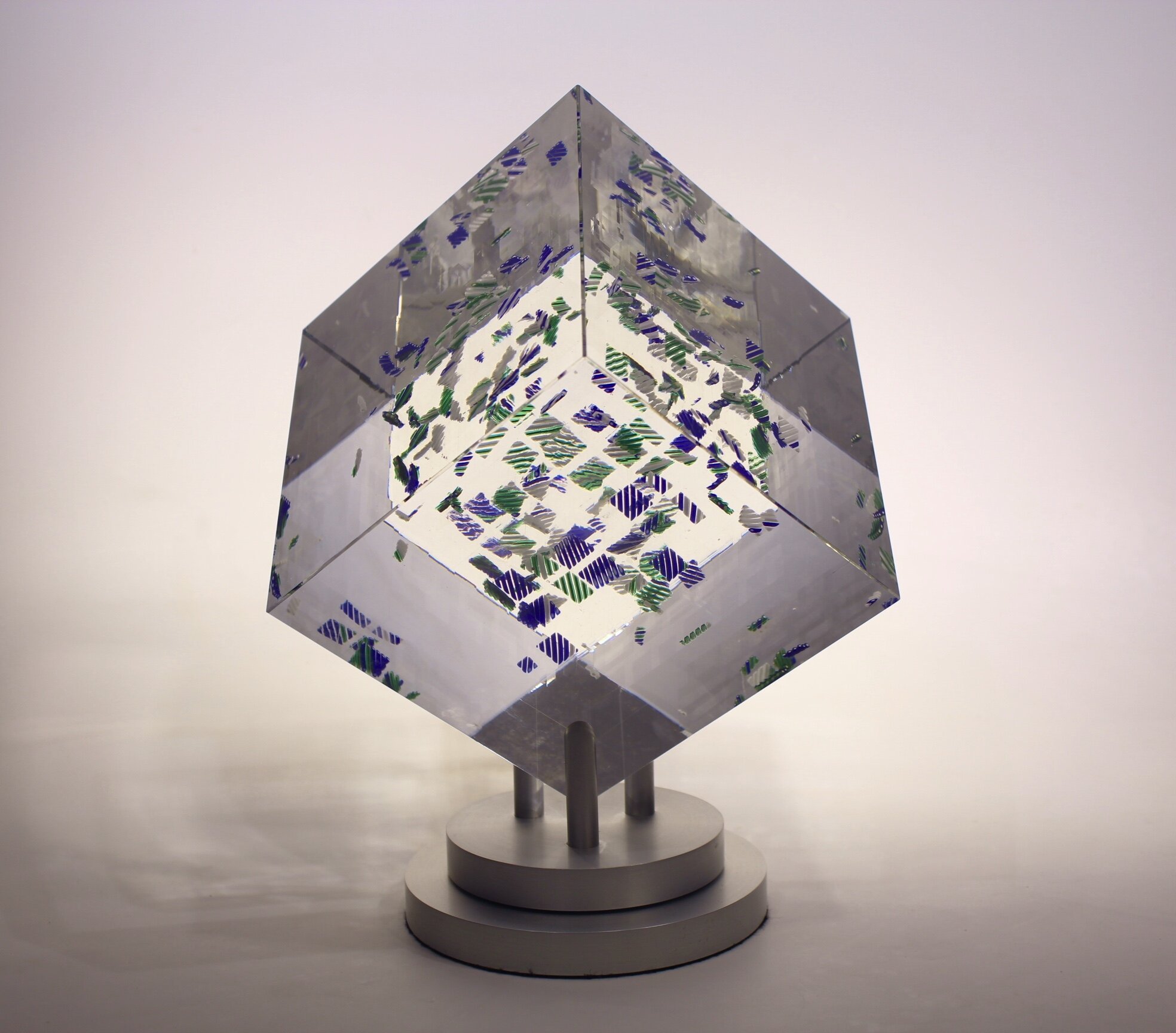

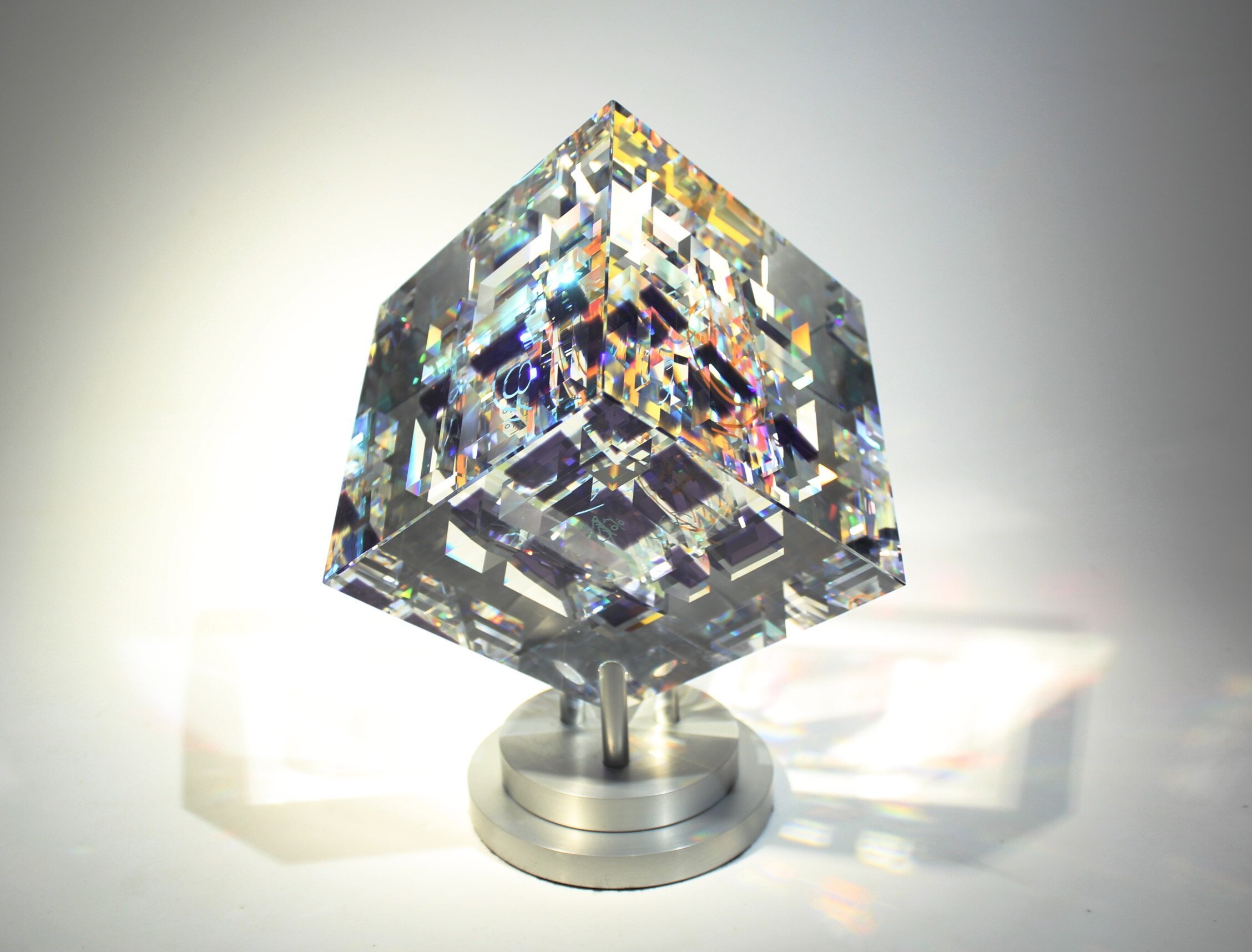

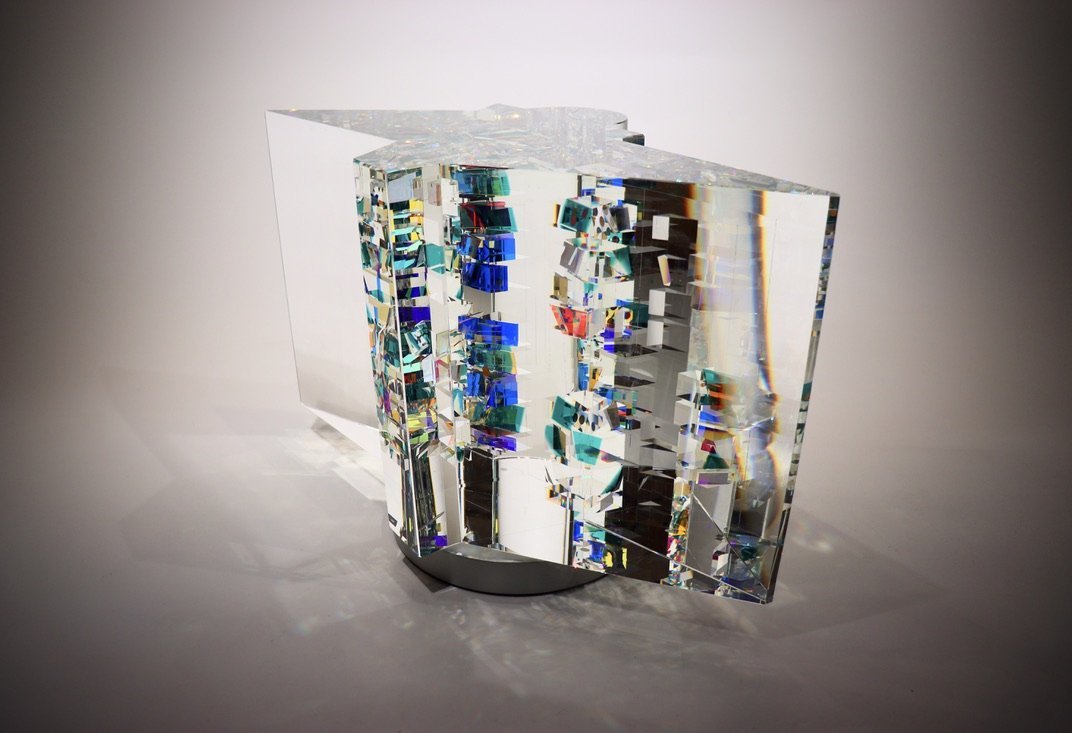

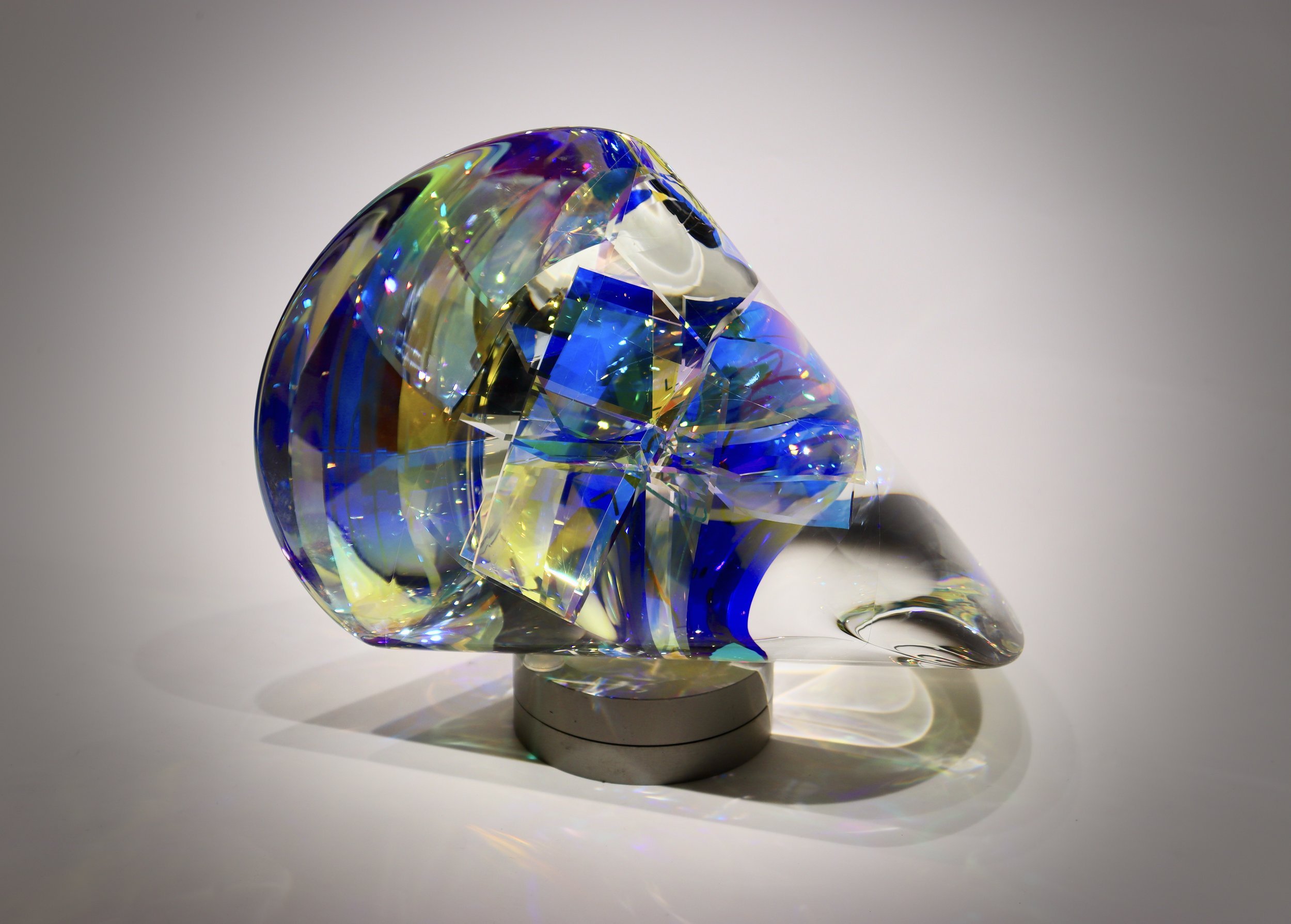

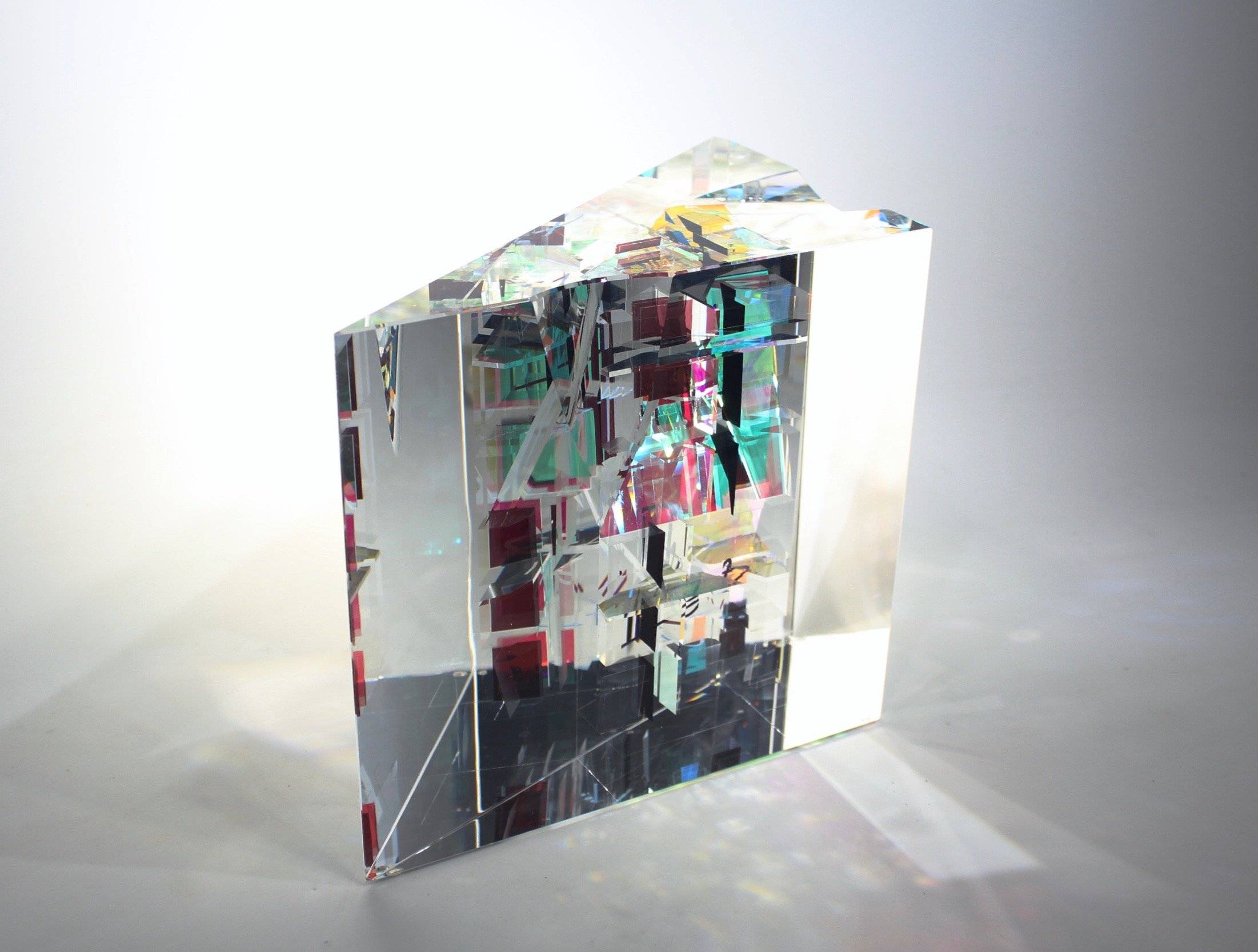

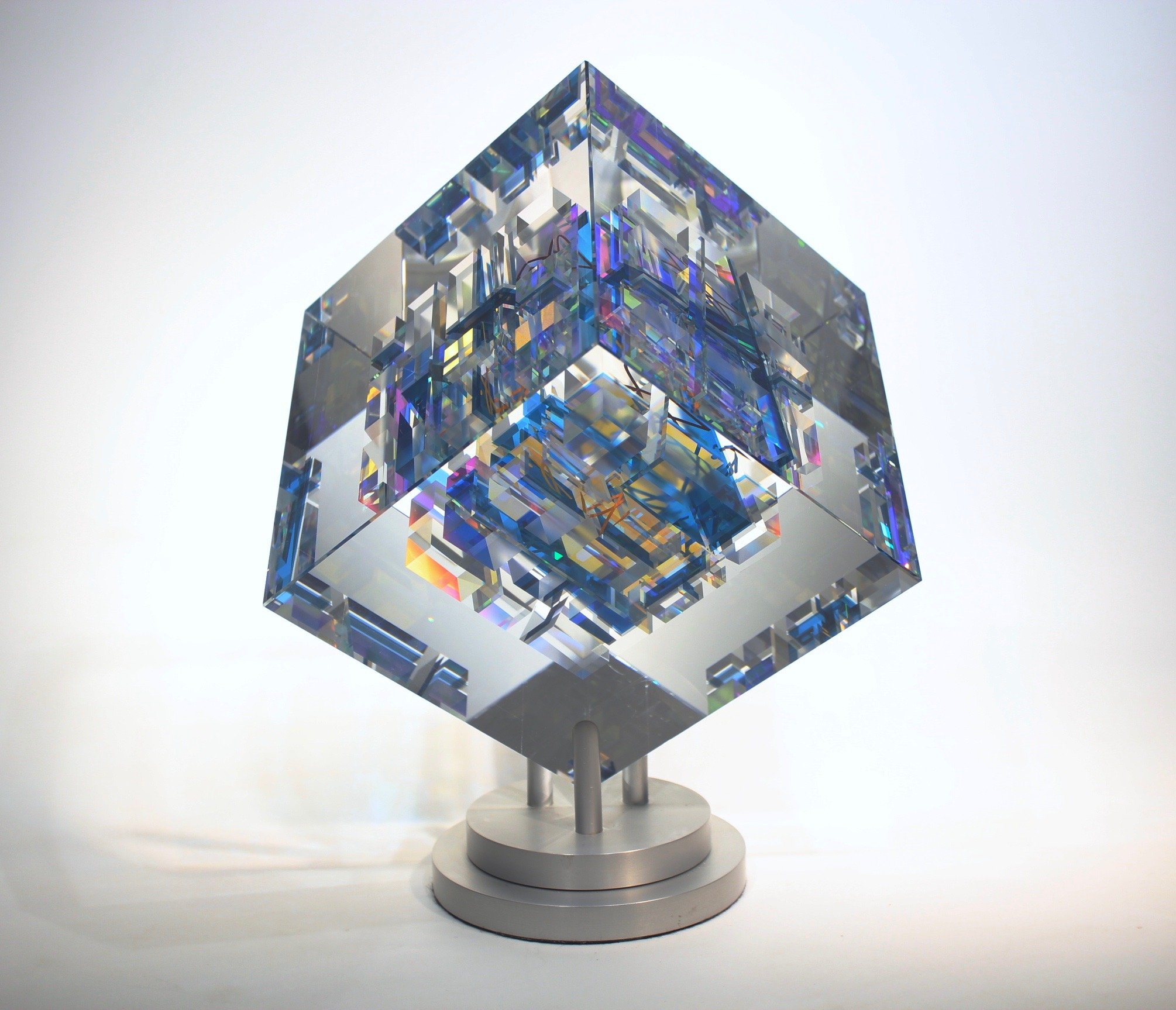

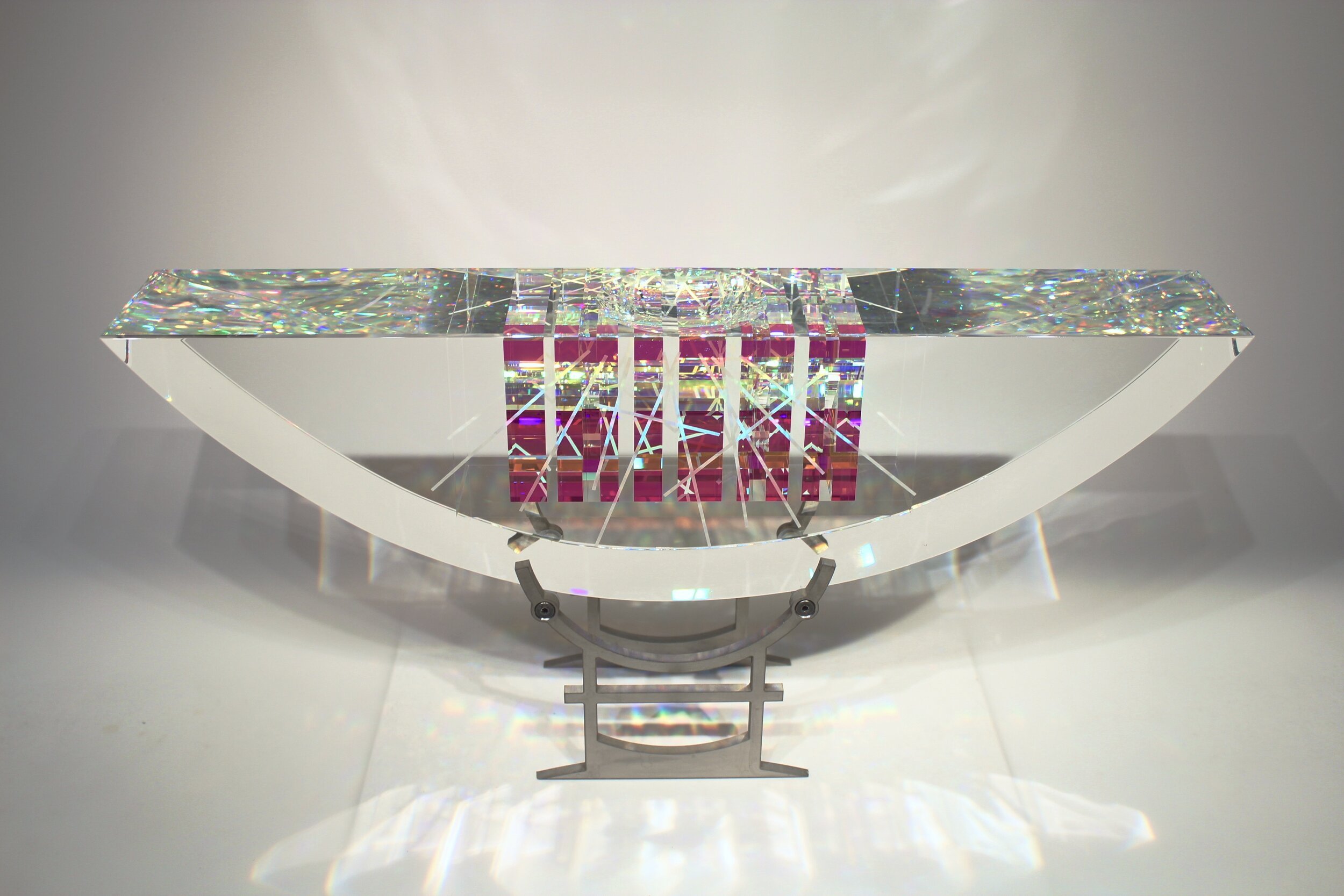

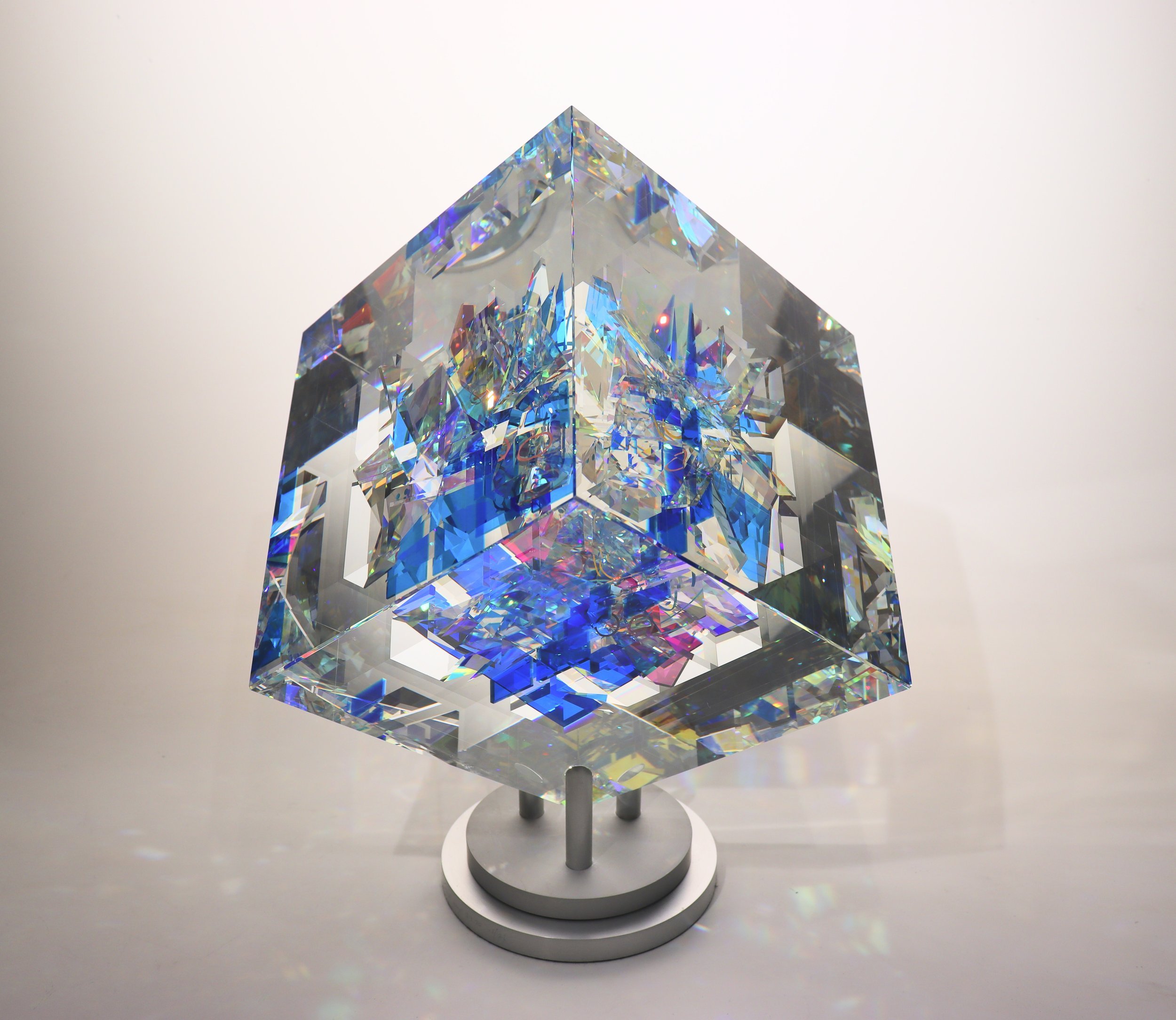

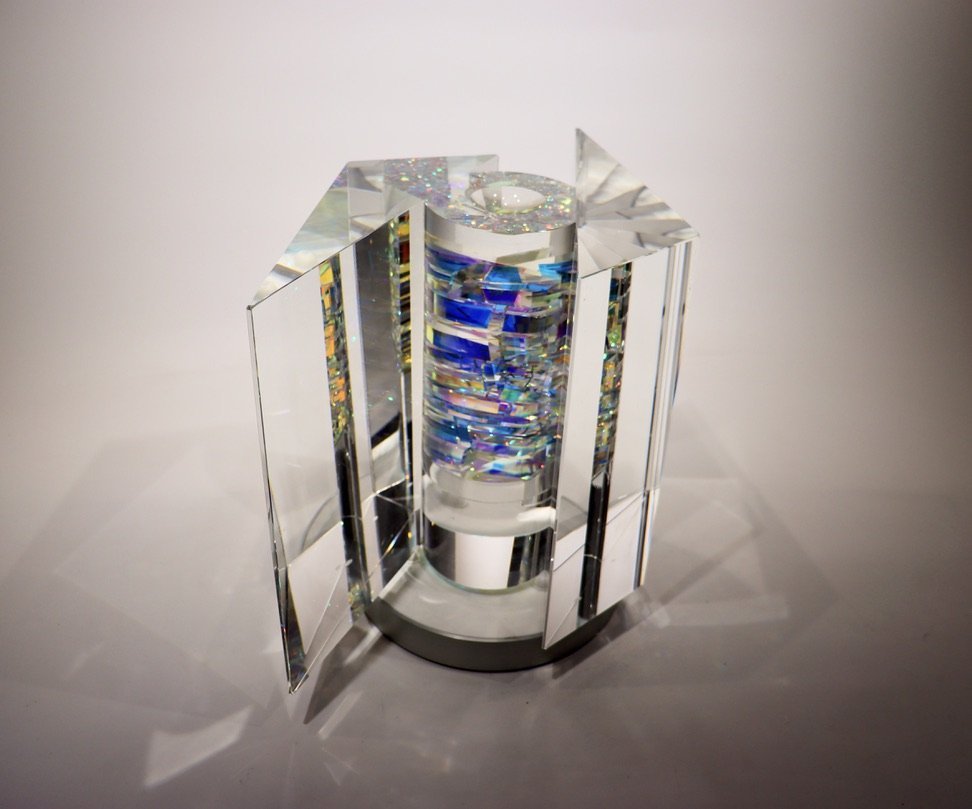

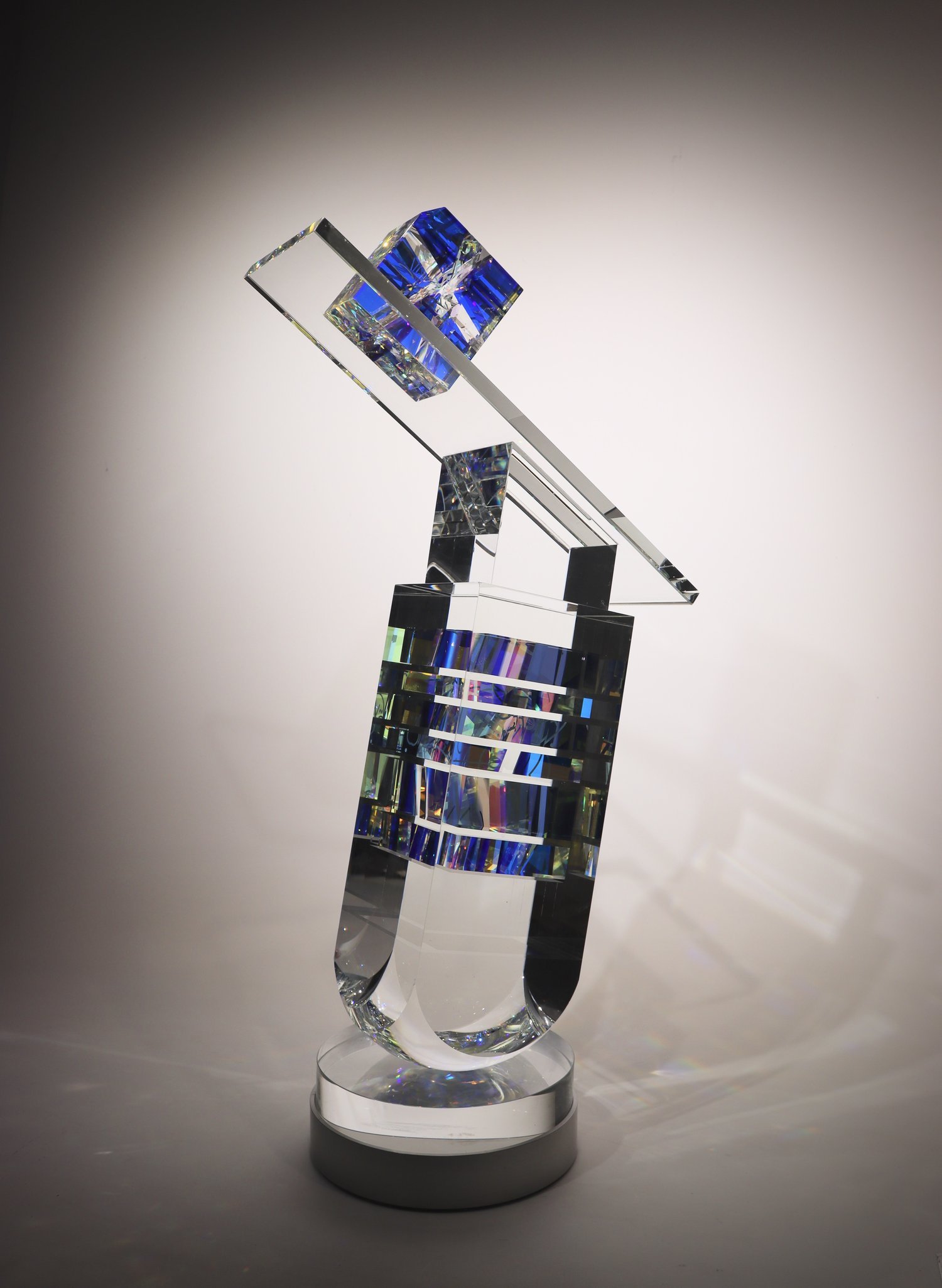

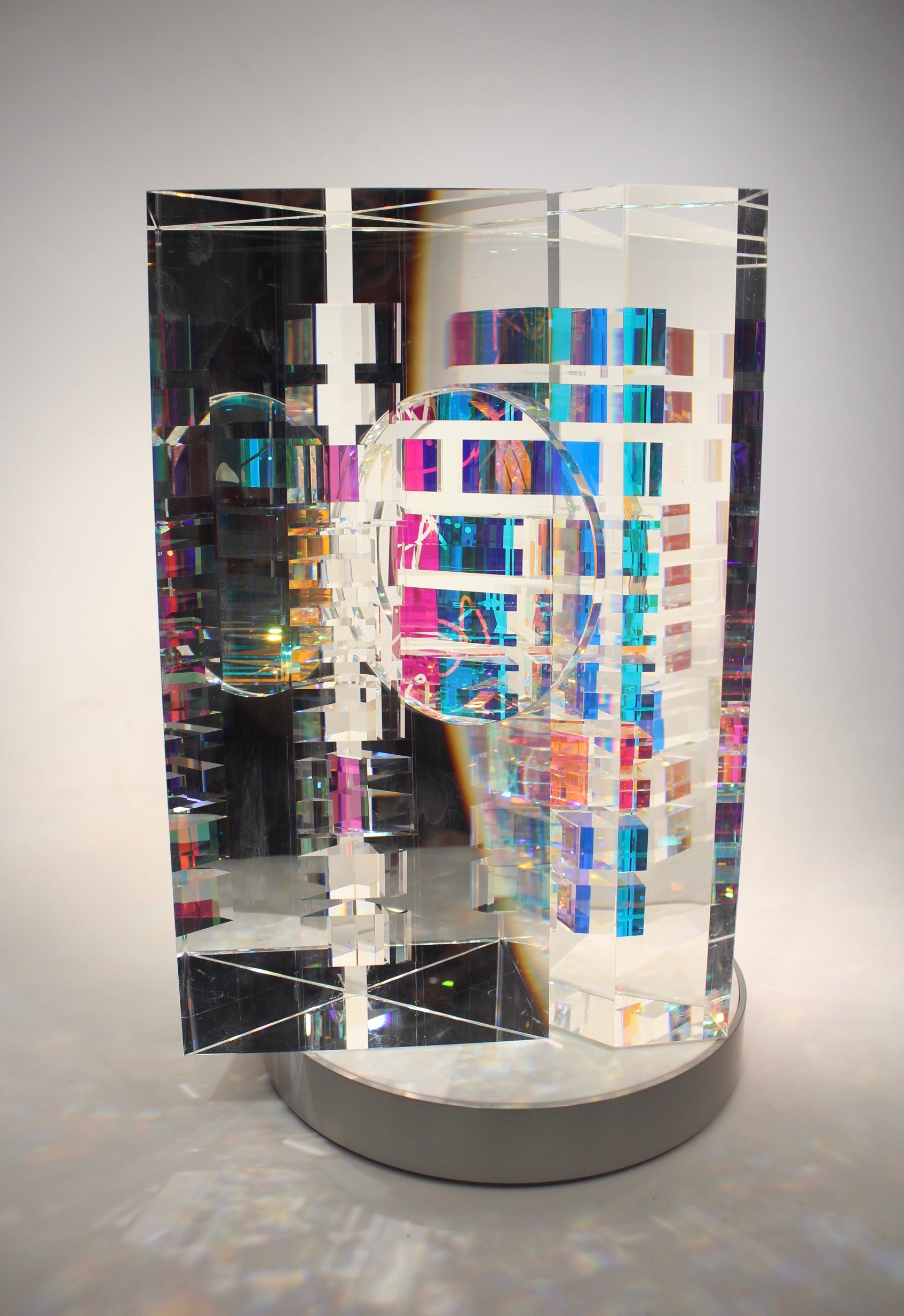

This is a presentation of recent pieces that are currently in private collections.

Toland's style has constantly evolved over the last 45 years as a glass sculptor.

THE PROCESS

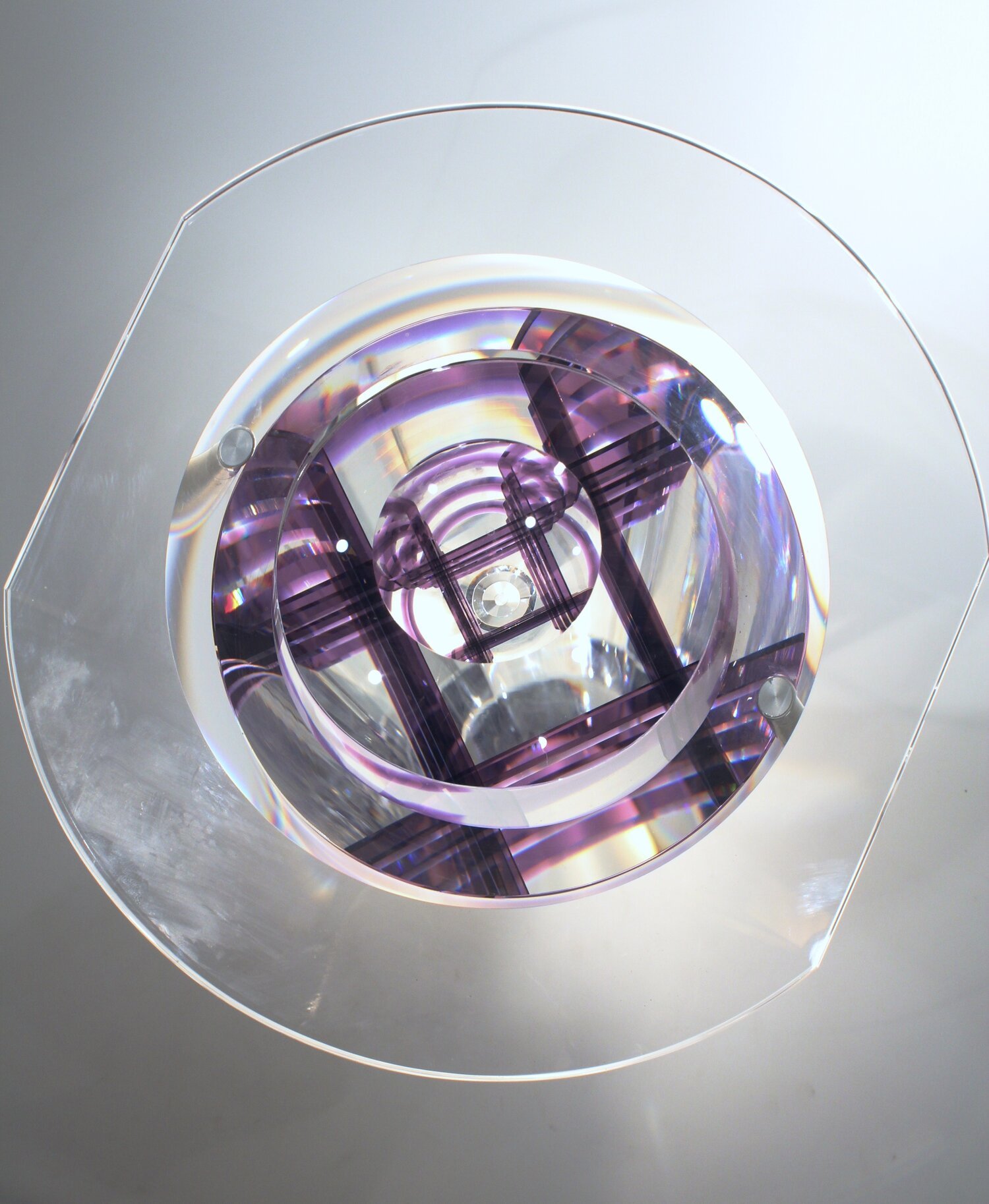

I use glass much like one might use stone. I use masonry saws to cut the rough blocks and then grind and polish the component pieces of the sculpture by hand. Optical adhesives hold everything together. On the interior, colored area I use a variety of coloring materials as well as leaded and non-leaded optical crystal. It often takes 6-8 weeks to bring a piece to completion.

Glue

A special optical epoxy is used to assemble the pieces. A two part epoxy mixing process involves lightly warming it, mixing it with a latte frother, and then putting the beaker in a vacuum chamber to pull out all of the gases. It's then put in a syringe and dispensed carefully.

Cut

A water cooled masonry saw with a diamond coated blade is used to cut the glass. Pieces are placed on hard foam to secure them

Polish

A variety of wet grinding wheels are used with progressively finer finishes and grits in order to smooth the rough cut of the saw. The final step is to encase the pieces in plaster to keep them flat while they are polished on a rociprolap. All of the edge beveling as well as curved surfaces are ground and polished by hand.